Brought to you by:

Walmart: Supply Chain Management

By: P. Fraser Johnson, Ken Mark

This case focuses on the supply chain strategy of Walmart. Set in 2019, it provides a detailed description of the company's supply chain network and capabilities. Data in the case allows students to…

- Length: 16 page(s)

- Publication Date: Jul 8, 2019

- Discipline: Operations Management

- Product #: W19317-PDF-ENG

What's included:

- Teaching Note

- Educator Copy

$4.95 per student

degree granting course

$8.95 per student

non-degree granting course

Get access to this material, plus much more with a free Educator Account:

- Access to world-famous HBS cases

- Up to 60% off materials for your students

- Resources for teaching online

- Tips and reviews from other Educators

Already registered? Sign in

- Student Registration

- Non-Academic Registration

- Included Materials

This case focuses on the supply chain strategy of Walmart. Set in 2019, it provides a detailed description of the company's supply chain network and capabilities. Data in the case allows students to compare Walmart's source of competitiveness with those of other retailers-both online including Amazon.com and traditional brick-and-mortar retailers, such as Target-to develop insights into the management of a large, complex, global supply chain network. As competition between Walmart and its online and offline competitors heated up, a key challenge for the company's president and chief executive officer was deciding what changes made to Walmart's expanding supply chain would best support its strategic objectives. What supply chain capabilities would Walmart need as its business model continued to evolve?

Learning Objectives

This case can be used in an undergraduate or MBA course in supply chain management, operations management, business strategy, international business, logistics, purchasing, or marketing. It can provide an introduction to supply chain management using a company with which most students are familiar. In doing so, it allows students to learn how Walmart has built up its supply chain capabilities over the past five decades, and how the company leveraged these capabilities to become the world's largest retailer. Combining the Walmart case with the "Amazon.com: Supply Chain Management" case (W18451) in back-to-back classes provides a powerful illustration of the differences between two leading companies and demonstrates the importance of alignment of supply chain competencies with organizational strategy. After completion of this case, students will be able to: Assess Walmart's supply chain and identify its key competitive advantages. Quantify Walmart's ability to generate value from its supply chain. Identify potential opportunities and challenges for Walmart to improve its supply chain. Analyze the effects of the opportunities and challenges facing Walmart on its growth and evolution.

Jul 8, 2019 (Revised: Sep 9, 2019)

Discipline:

Operations Management

Geographies:

United States

Industries:

Retail trade

Ivey Publishing

W19317-PDF-ENG

We use cookies to understand how you use our site and to improve your experience, including personalizing content. Learn More . By continuing to use our site, you accept our use of cookies and revised Privacy Policy .

- Automation Supply Chain

- Continuous Improvement

- Last Mile \ Delivery

- Logistics Training and Resources

- Manufacturing

- Procurement/Negotiations

- Supply Chain

- Warehouse/Fulfillment

- Artificial Intelligence

- Entrepreneur

- Robots & Drones

- Self-Driving Vehicles

- *SCM Social Media Channels

- SCT Discussion

WALMART SUPPLY CHAIN BEST PRACTICES | MBA CASE STUDY

Let’s take a look at Walmart Supply Chain best practices. Walmart has one of the most sophisticated and efficient supply chains in the world. It has been constantly evolving since the company was founded in 1962.

In the early days, Walmart’s supply chain was relatively simple. The company would order goods from manufacturers and then ship them directly to its stores. However, as Walmart grew, its supply chain became more complex. The company began to work with more suppliers and to move goods around the world.

In the 1980s, Walmart began to invest heavily in technology to improve its supply chain. The company implemented a computer system that allowed it to track inventory levels and forecast demand. It also began to use radio frequency identification (RFID) tags to track the movement of goods.

These investments helped Walmart to improve the efficiency of its supply chain. The company was able to reduce costs, improve accuracy, and speed up the delivery of goods to its stores.

Walmart Today

Today, Walmart’s supply chain is a global network that spans over 10,500 stores in 24 countries. The company works with over 100,000 suppliers and moves billions of products each year.

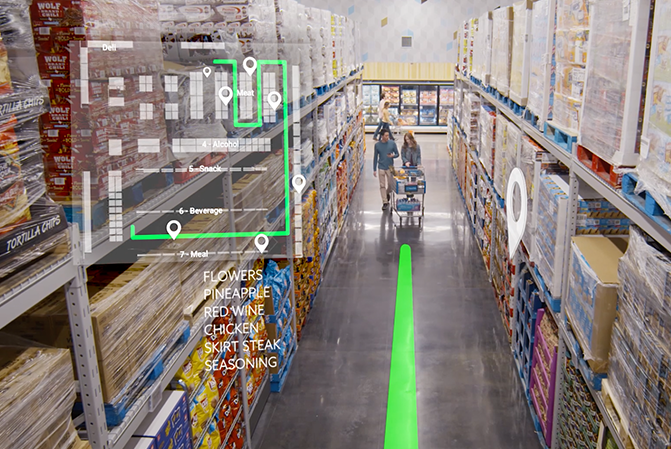

Walmart’s supply chain is still evolving. The company is constantly looking for ways to improve efficiency and sustainability. It is also investing in new technologies, such as artificial intelligence and blockchain, to further streamline its operations.

Walmart’s supply chain is a major competitive advantage. It allows the company to offer low prices and a wide selection of products to its customers. It also helps Walmart to respond quickly to changes in demand.

Here are some of the key factors that have contributed to the success of Walmart’s supply chain:

- Centralization: Walmart has centralized its supply chain operations. This has allowed the company to improve efficiency and coordination.

- Technology: Walmart has invested heavily in technology to improve its supply chain. This includes the use of RFID tags, computer systems, and big data analytics.

- Collaboration: Walmart works closely with its suppliers to improve the efficiency of its supply chain. This includes sharing data and working together to solve problems.

- Sustainability: Walmart is committed to sustainability. This is reflected in its supply chain, where the company is working to reduce waste and emissions.

Walmart’s supply chain is a complex and ever-evolving system. However, the company’s commitment to efficiency, collaboration, and sustainability has helped it to create one of the most successful supply chains in the world.

Walmart and P&G Partnering

Walmart and P&G partnered to make a breakthrough in supply chain by sharing data and collaborating on new technologies.

In the late 1980s, Walmart was struggling to keep up with demand. The company was growing rapidly, and its supply chain was not able to keep pace. P&G, on the other hand, was having difficulty getting its products onto Walmart’s shelves.

The two companies decided to partner to find a solution. They began by sharing data about inventory levels and customer demand. This allowed them to better coordinate their supply chains and ensure that the right products were in the right place at the right time.

Walmart and P&G also worked together to develop new technologies to improve their supply chain efficiency. For example, they developed a system called Continuous Replenishment Program (CRP). CRP uses real-time inventory data to automatically trigger shipments of products from P&G to Walmart stores.

This partnership has been a huge success for both companies. Walmart has been able to improve its customer service and reduce costs. P&G has been able to increase sales and improve its profitability.

Here are some of the specific benefits that Walmart and P&G have gained from their partnership:

- Reduced inventory levels

- Increased sales

- Improved customer service

- Reduced costs

- Improved profitability

The partnership between Walmart and P&G is a model for how companies can work together to improve their supply chains. By sharing data and collaborating on new technologies, companies can create a more efficient and effective supply chain that benefits everyone involved.

Walmart and Retail Learning Resources

- 5 Amazing Warehouse Robots for Fulfilment and Distribution Centers.

- Amazon Drone Delivery in California. It’s Happening.

- Amazon Reveals Warehouse Robots For Sorting Packages and Fully Autonomous Mobile Robot.

- How Amazon’s Supply Chain Management Strategy Works?

- How Walmart Is Betting Big On Stores To Catch Amazon In E-commerce.

- How Walmart will use autonomous driverless delivery to boost online sales.

- Sam Walton and Jeff Bezos Leadership and Supply Chain Quotes.

- Skirting Supply Chain Chaos – Amazon.

- Supply Chain Quotes: Take it to the next level.

- Understand Lean and Agile Supply Chain strategies.

- Walmart CEO Doug McMillon Quotes .

- Why Use an Agile Supply Chain Strategy?

How is Nike changing the supply chain game? MBA Case Study.

Is your warehouse ready to handle omnichannel logistics?

Can Walmart Catch Amazon In E-commerce?

Saturday Morning Meeting: Amazon vs. Walmart

Skechers distribution center

Target Supply Chain Strategy to Beat Amazon and Walmart’s Fast Delivery.

Logistics Viewpoints

A complete analysis of logistics trends, technologies, and services

Walmart’s Massive Investment in a Supply Chain Transformation

Supply Chain Planning | By Steve Banker • 05/10/2021

Walmart has been very open about what it takes to compete with Amazon. Following their fourth quarter results, top executives talked about their supply chain and omnichannel strategy at a high level. Brett Biggs, an executive vice president at Walmart, summarized the investments by saying the retailer is spending on increased fulfillment capacity, supply chain, automation, and technology. This new infrastructure will allow the retailer to expand ecommerce assortment while reducing both shipping time and cost. Walmart is making investments in warehouse automation in distribution centers to deliver aisle and department-ready pallets to stores. Walmart is also investing pickup and delivery capacity.

On March 21st, David Guggina – the senior vice president supply chain, product, and engineering – filled in more detail on the specifics of their supply chain journey while speaking at Blue Yonder’s virtual Icon user conference. Blue Yonder is a leading provider of supply chain software solutions including several solutions that will be mentioned in this article – demand management, inventory optimization, replenishment, warehouse management, warehouse control systems, yard management, and transportation management.

Walmart’s fiscal 2021 ended on January 31 st . With $555 billion in sales, the world’s largest retailer grew by 6.8%. Walmart’s operating income was $22.5 billion, 4.1% of sales.

Amazon is smaller. Amazon’s fiscal year ended on December 31 st . The company had $341 billion in retail revenues. Amazon is less profitable. Retail operations had an operating income of $9.4 billion, just 2.8% of sales. But with 38% year over year growth, they are growing much faster than Walmart. If this continues, it will not be too many years before Amazon is the world’s largest retailer.

Around the world, ecommerce is growing much faster than in-store sales. Walmart knows this. Brick and mortar retailers that do not have a strategy to grow sales based on an omnichannel strategy are going out of business with an increasing frequency. Walmart has been working to pivot to omnichannel for several years to help speed growth. For Walmart, “omnichannel” is defined as a customer-centric experience that seamlessly integrates ecommerce and retail stores into an offering that saves time for consumer.

Walmart’s U.S. ecommerce sales contributed approximately 5.4% of comparable sales last year. Walmart defines ecommerce sales as those that originate online but which be fulfilled by either dedicated ecommerce fulfillment sites or by leveraging their stores. The store omnichannel services include pickup at store, ship from store, and digital pharmacy fulfillment options. The company has 7,300 pickup and 5,200 delivery locations globally.

The US is where Walmart’s digital transformation is centered. Walmart’s investment in ecommerce, supply chain, and technology in the US was over $11 billion over the last two years. For retailers, remodeling stores and building new stores is usually where most of the capital has historically been spent. At Walmart, their digital transformation – spending on ecommerce and supply chain technologies, combined with new investments in supply chain infrastructure – represented 72% of their strategic capital expenditure in the US for their 2020 and 2021 fiscal years.

Mr. Guggina talked about how Walmart is approaching their supply chain transformation. “For many of our customers, saving time is as important as saving money.” That has led to growth in ecommerce. But Walmart will not abandon their strategy of being a low-cost provider – what the company calls “everyday low prices.” Low prices translate into having a focus on cutting costs; this in turn means having an efficient supply chain.

But there is tension between price leadership and service. In a store, customers have access to 100 to 150,000 stock keeping units (SKUs). But when a consumer goes online, they can access hundreds of millions of items. But there is a challenge around slow selling items. Where should slow movers be held so that orders can be fulfilled both economically and with speed.

Delivering many items ordered online quickly depends upon shorter lead times and the ability to support a variety of fulfillment options such as curbside pickup or ship from store. Distribution centers that traditionally just replenished a given set of stores will be increasingly asked to also fulfill ecommerce orders. Mid-mile and last mile transportation capabilities need to be improved. “That is a steep ask for any supply chain,” Mr. Guggina stated.

This is where Walmart seeks more “precision.” The use of demand management, inventory optimization, and replenishment applications can help this retail behemoth achieve much better inventory placement and fulfillment flexibility. Investing in supply chain applications also, Mr. Guggina asserts, helps them with their “relentless cost focus.”

The pandemic created a challenging year for their supply chain. “I’m glad we had our leadership and strategy in place,” Mr. Guffina said. “The pandemic propelled our omni strategy ahead by 3 to 5 years.” Pick up at store and home deliveries grew quickly because of the pandemic.

So besides forecasting, inventory optimization, and replenishment, how are those billions of dollars being spent in the supply chain area?

Walmart is reducing packaging waste by right sizing packaging; for some products packaging might not be required at all. This initiative requires capturing product dimensions and other product attributes with higher accuracy. The packaging algorithms do not work if this data is not up to date.

In their distribution centers, Walmart is modernizing their warehouse management system (WMS). The system, which will launch later this year, will have better labor planning, as well as providing better inventory control.

Walmart is making extensive investments in warehouse automation. The company has deployed autonomous mobile robots for moving pallets. The retailer is also investing in the use of automation for picking/putting to and from containers. There are large investments in sortation equipment; sortation systems automatically sort products down the correct shute as they move through a warehouse on a conveyor. When it comes to these projects, warehouse control systems are used to interconnect the automation assets – the hardware – with the warehouse management system software.

Investment is being made in a highly automated warehousing solution from Witron surrounding produce. Vegetables and fruits will be able to be delivered more quickly and cheaply as a result.

In transportation, Walmart is engaged in numerous projects. The company is doing a proof of concept to see if trucks can move about autonomously in their yards. The autonomous trucks will need to be integrated to an improved yard management system for this. That will lead to better flow in their yards.

There are experiments with over the road autonomous trucks. There is work being done to improve optimization associated with trucks moving inbound from suppliers to their distribution centers. There is also a project surrounding freight matching and freight pay. Not surprisingly, a command center visibility solution is being developed.

There are also new tools and applications for the cab of a truck. Their 11,000 drivers will have new onboard computers. Last mile will be improved as stores increasingly become a starting point for consumer deliveries.

“We are moving faster than ever, Mr. Guggina said. “We are partnering with Blue Yonder to help to continue to transform our supply chain.” Walmart has been known as a company that developed many of their applications in-house. “The days of buy versus build are over.” Walmart has shifted being a buyer of supply chain software.

Over my 25-year career, I have heard executives from several supply chain software vendors say that Walmart was using their solution in some part of their operations. Unfortunately, they said, they were not allowed to publicly name Walmart as a customer. Having a Walmart executive give the keynote at the Blue Yonder user conference, and publicly name Blue Yonder as a key solution partner, is a noteworthy occurrence.

Share this:

- Supply Chain & Sustainability Leadership Multimedia Suite

Walmart Supply Chain: What Makes It (Still) So Successful

By Meredith Flora Last updated on February 23, 2024

Need Help With Order Fulfillment? ShipBob Can Help.

Subscribe for more.

Enjoying this article? Join the tens of thousands who get the latest from ShipBob’s blog emailed every other week.

Table of Contents

What makes Walmart’s supply chain so successful?

Walmart and shipbob’s winning fulfillment combo, walmart supply chain faqs.

With a revenue of over $570 billion , Walmart continues to rank number one on Fortune’s Global 500 list. This marks their ninth consecutive year at the top position, making Walmart the largest company in the world by revenue.

Walmart’s success can be attributed to having their own supply chain to streamline fulfillment and cut down on costs. It also provides them with more control over their logistics network .

In this article, we take a closer look at the Walmart supply chain and why it continues to be so successful decades later.

Walmart’s supply chain success can be attributed to their tactful decisions to start investing in the right initiatives, including technology and expanding their logistics network, to provide value in the ecommerce space.

Below we break down the various initiatives that has made Walmart’s supply chain successful.

Early investment in supply chain optimization

Walmart’s focus on optimization is one of the largest factors contributing to the brand’s supply chain success.

The retail giant is constantly striving to improve existing systems and processes to create an optimized and efficient supply chain to provide their customers with “everyday low prices” — one of the company’s unique (and renowned) selling points.

Among the many supply chain optimization strategies, the company places great emphasis on omnichannel — multiple channels available to its customers. Walmart’s Marketplace creates a home for thousands of retail stores with the ultimate goal to save time for the consumer.

Walmart also provides multiple marketplace fulfillment options, such as in-store pickup, ship from store, and even digital pharmacy fulfillment. Globally, Walmart offers 7,000+ pickup locations and 5,000+ delivery locations.

Fine-tuning the supply chain management system

Walmart is constantly striving to improve their supply chain management system.

From the get-go, the company started removing links within the supply chain and purchased goods in bulk to be transported directly to their stores.

They then began working directly with manufacturers and distributors to cut out the middleman to further streamline the supply chain.

This approach plays a key role in their supply chain success. With fewer players in the supply chain, the company can lower costs and cut back on lead times to offer quick and affordable fulfillment .

Developing strong relationships with vendors early on

Walmart’s strong relationships with vendors have played a major role in their supply chain success. They go straight to the source and identify vendors who can provide them with the best price and can meet their high-volume demands.

Walmart establishes strategic partnerships with these vendors, guaranteeing them consistent business through long-term, high-volume purchases. In return, the company can enjoy wholesale prices, which keeps customer prices competitive throughout the years.

To further strengthen these relationships, Walmart also establishes open communication networks with their vendors. This allows them to improve the flow of inventory within the supply chain and anticipate possible disruptions before they escalate into larger problems, such as backorders , stockouts, and delivery delays.

Outsourcing inventory control with vendor managed inventory (VMI)

Walmart has further strengthened and simplified their supply chain by implementing a vendor management inventory (VMI) model.

VMI involves suppliers managing their own inventory that’s stored in Walmart’s warehouses. With this approach, the company puts the responsibility of managing inventory in the hands of suppliers, so they can save time and money on inventory management.

With an electronically backed VMI system, suppliers have access to Walmart’s inventory data, allowing them to keep track of real-time inventory levels and sales. This makes it easy monitor how much stock is available and how certain products are sold.

Based on this information, they can see when they need to send more inventory to Walmart and keep their stock replenished.

This simplified inventory management model results in fewer delays in replenishment and reduces stockouts. It’s particularly useful since Walmart deals with hundreds of thousands of SKUs from thousands of suppliers, which can get complicated and expensive to manage.

By transferring some of the inventory control activities to the vendors, the company can save time and focus on tasks that need to be handled in-house.

It also means that Walmart doesn’t need to spend more on dedicated personnel to manage the inventory coming from each supplier, which results in lower costs for them. All Walmart has to do is monitor the transport of inventory from warehouses to their stores.

Capitalizing on the power of technology

As Walmart undergoes a digital transformation , they’re making extensive investments in supply chain digitization and infrastructure. These investments have contributed to the successful supply chain that we see today.

Between 2019 and 2020, 72% of Walmart’s strategic capital expenditures were attributed to supply chain transformation , which includes supply chain technologies, infrastructure, and ecommerce. During this period, the company spent more than $11 billion.

These investments have resulted in faster, more flexible fulfillment , and more accurate demand forecasting .

Walmart also uses technology in their initiative to reduce packaging waste. Packaging algorithms make it easier to find the right-size packaging for each product by accurately capturing product dimensions and other attributes.

Additionally, Walmart has implemented an advanced warehouse management system (WMS) in their distribution centers . This more nuanced WMS supports better inventory control and labor planning to streamline their supply chain operations .

Overall, one of the largest technological investments they’ve made is in automation. Autonomous mobile robots are helping warehouse staff move pallets, while other automation tools are used for picking items or packing them inside containers.

Walmart has also made significant investments in sortation equipment, which will automatically sort products and allocate them to the right locations within the warehouse. Robust warehouse control systems help to establish a link between these automation equipment and the WMS.

ShipBob is an official Walmart partner and participates in Walmart’s TwoDay delivery program .

ShipBob’s fulfillment platform integrates with Walmart Marketplace to display free 2-day delivery badging and fulfills 2-day orders approved by marketplace sellers.

Here is how ShipBob’s integration with Walmart works.

Two-day shipping

By connecting ShipBob with Walmart , businesses can provide two-day shipping with 100% coverage across the continental United States.

You can connect your Walmart store to ShipBob in minutes, sync your inventory, and choose what fulfillment center locations to send inventory to.

Your “Free 2-day delivery” badge will appear prominently near the “Add to Cart” button, which captures attention and generates, on average, 50% more conversions.

ShipBob’s on-time delivery rate is over 95%, which provides merchants with reliability and speed.

“DTC is our bread and butter, and with ShipBob we can offer 2-day shipping, gift notes, and other aspects of the modern delivery experience that consumers want.” Aaron Patterson, COO of The Adventure Challenge

Warehousing

ShipBob offers warehousing solutions to help you manage your inventory more efficiently. When you outsource fulfillment to ShipBob, our team of fulfillment experts take care of the entire process of receiving, storing, and managing your inventory.

By storing your inventory across one or more fulfillment center location, you benefit from lower warehousing costs while also improving delivery speeds.

Once ShipBob receives your inventory and orders are placed on Walmart.com, they are automatically sent to ShipBob to be picked, packed, and shipped.

From the ShipBob fulfillment platform, you can track activity, manage SKUs and inventory levels across locations, and view storage costs.

“ShipBob’s analytics are a huge bonus for a merchant looking to partner with a single 3PL that has a built-in order management tool. I was so stoked about being able to see the optimized layout of where you should be distributing your inventory is great. Having inventory and warehouse management capabilities built into your 3PL is such a value-add, especially for smaller companies.” Juliana Brasil, Director of Operations at Food Huggers

Inventory management

ShipBob’s inventory management tools further simplify the fulfillment process by providing a single dashboard to view real-time inventory levels across locations.

With real-time insight into inventory, you can get ahead of inventory replenishment, access data to improve demand forecasting, and make better business decisions.

You can even keep track of the number of units sold per day, so you know when to prepare for inventory replenishment. From the ShipBob dashboard, you can use the inventory data available to set reorder points to prevent stockouts .

Walmart integration

ShipBob’s integration with Walmart improves product visibility on Walmart Marketplace while also having your orders fulfilled through ShipBob.

Thanks to ShipBob’s omnichannel fulfillment capabilities, your inventory levels are updated in real time to reflect the purchases across all your sales channels, including Walmart. This way, you don’t end up accidentally selling more products than you have in stock.

With the Walmart integration, you can get your products in front of millions of customers and provide a seamless order fulfillment experience.

To learn more about how ShipBob partners with Walmart, contact ShipBob today.

Here are answers to the top questions about Walmart supply chain.

Does Walmart have its own supply chain?

Yes, Walmart has one of the largest supply chains in the world. Their nuanced supply chain establishes a more direct relationship between vendors and end consumers. Walmart runs their own distribution centers and partners with logistics companies like ShipBob to further expand their supply chain network.

What is Walmart’s supply chain strategy?

Walmart’s supply chain strategy is highly focused on direct, long-term relationships with manufacturers, distributors, and ecommerce businesses. The goal is to reduce the number of touchpoints within the supply chain to reduce lead times and speed up fulfillment. Walmart also heavily invests in supply chain technology to improve efficiency and accuracy throughout their network.

What are the advantages of selling on Walmart Marketplace?

Selling on the Walmart Marketplace will give you access to the retailer’s 120+ million monthly customers. This means you can get your products in front of a massive audience, which will improve the chances of boosting sales. Moreover, the Walmart Marketplace doesn’t charge you any monthly fees. Marketplace fees are commission-based, which means you only pay a fee when you make a sale.

Written By:

Meredith Flora

Meredith is a Content Marketing Specialist at ShipBob, where she writes articles, eGuides, and other resources to help growing ecommerce businesses master their logistics and fulfillment.

Read all posts written by Meredith Flora

Subscribe to our blog

Join tens of thousands of ecommerce brands to get more articles like this and our latest resources delivered to your inbox.

Just for you

Latest tips to improve ecommerce logistics.

How to Measure and Improve Your Supply Chain Metrics

Reverse Logistics Meaning and Process Explained

How iVYVERDURE Got Time Back For Growth by Outsourcing to ShipBob [Case Study]

Shipbob offers outsourced fulfillment and a wms if you have your own warehouse. request a quote by filling out the form..

A fulfillment expert will get back to you shortly.

Loading Job...

Job description:.

Walmart: Supply Chain Management

About This Product

This operations management case study focuses on the supply chain strategy of Walmart. Set in 2019, it provides a detailed description of the company’s supply chain network and capabilities. Data in the case allows students to compare Walmart’s source of competitiveness with those of other retailers—both online including Amazon and traditional brick–and-mortar retailers, such as Target—to develop insights into the management of a large, complex, global supply chain network. As competition between Walmart and its online and offline competitors heated up, a key challenge for the company’s president and chief executive officer was deciding what changes made to Walmart’s expanding supply chain would best support its strategic objectives. What supply chain capabilities would Walmart need as its business model continued to evolve?

Learning Objectives

This Walmart Supply Chain Management case study can be used in an undergraduate or MBA course in:

- Supply chain management

- Operations management

- Business strategy

- International business

It can provide an introduction to supply chain management using a company with which most students are familiar. In doing so, it allows students to learn how Walmart has built up its supply chain capabilities over the past five decades, and how the company leveraged these capabilities to become the world’s largest retailer. Combining the Walmart case with the Amazon.com: Supply Chain Management case in back-to-back classes provides a powerful illustration of the differences between two leading companies and demonstrates the importance of alignment of supply chain competencies with organizational strategy.

After Completion of This Case Students Will Be Able To:

- Assess Walmart’s supply chain and identify its key competitive advantages.

- Quantify Walmart’s ability to generate value from its supply chain.

- Identify potential opportunities and challenges for Walmart to improve its supply chain.

- Analyze the effects of the opportunities and challenges facing Walmart on its growth and evolution.

- Additional Details

- Supplemental Products

- Supporting Materials

- SUGGESTED TOPICS

- The Magazine

- Newsletters

- Managing Yourself

- Managing Teams

- Work-life Balance

- The Big Idea

- Data & Visuals

- Reading Lists

- Case Selections

- HBR Learning

- Topic Feeds

- Account Settings

- Email Preferences

How Walmart Canada Uses Blockchain to Solve Supply-Chain Challenges

- Kate Vitasek,

- John Bayliss,

- Loudon Owen,

- Neeraj Srivastava

The system has drastically reduced payment disputes with freight carriers.

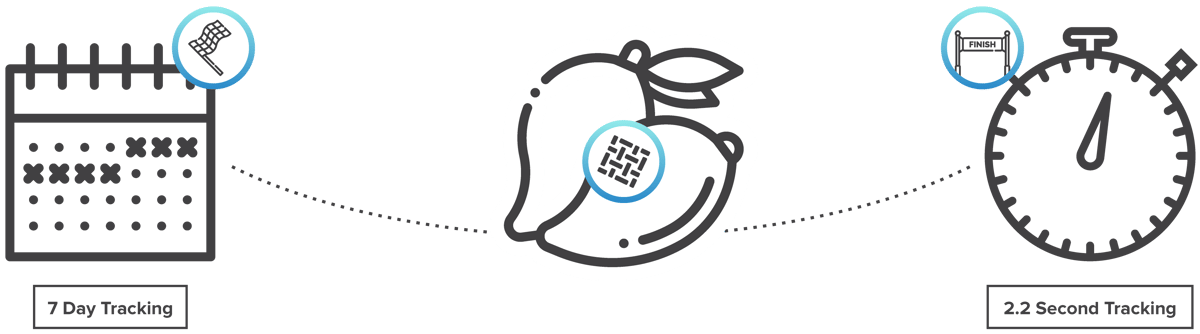

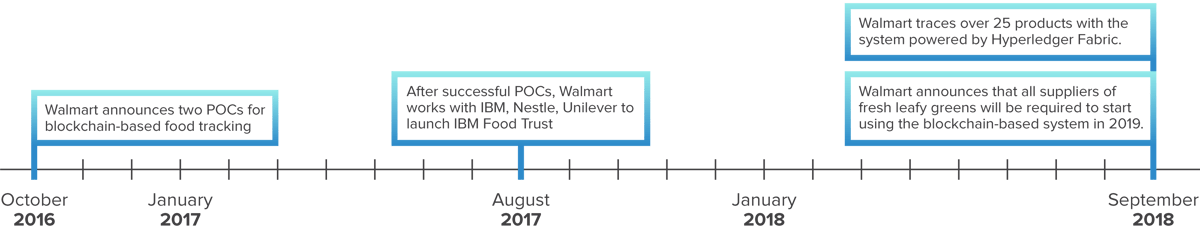

Walmart Canada applied blockchain to solve a common logistics nightmare: payment disputes with its 70 third-party freight carriers. To solve the problem it built a blockchain network. The system has not only virtually eliminated the payments problem; it also has led to significant operational efficiencies. This article offers five lessons on how to create a blockchain network for improving business processes.

Walmart has long been known as a leader in supply chain management. However, its prowess could not insulate it from a problem plaguing the transportation industry for decades: vast data discrepancies in the invoice and payment process for freight carriers, which required costly reconciliation efforts and caused long payment delays. Then Walmart Canada pioneered a solution: It employed blockchain, a distributed-ledger technology, to create an automated system for managing invoices from and payments to its 70 third-party freight carriers.

- Kate Vitasek is a member of the graduate and executive education faculty of the University of Tennessee, Knoxville’s Haslam College of Business, where she leads the university’s research and courses on highly collaborative win-win “vested” strategic business relationships.

- JB John Bayliss is an executive vice president and the chief transformation officer at Walmart Canada.

- LO Loudon Owen is chief executive officer of DLT Labs, a next-generation data management software company specializing in supply chain management and financial services.

- NS Neeraj Srivastava is a founder and the chief technology officer of DLT Labs, a next-generation data management software company specializing in supply chain management and financial services.

Partner Center

The marketplace for case solutions.

Walmart: Supply Chain Management – Case Solution

The Walmart: Supply Chain Management case study discusses the cost-saving strategy of the company and its supply chain management strategy. It focuses on how the company manages its supply chain in comparison with its competitors.

P. Fraser Johnson and Ken Mark Harvard Business Review ( W19317-PDF-ENG ) July 08, 2019

Case questions answered:

- Analyze the Walmart supply chain. Do you think their capabilities are a competitive advantage for Walmart? Why yes or why not?

- How is Walmart managing its supply chain? Compared it with its competitors?

- What are the most important business challenges Walmart faces and what implications do they have have for its supply chain?

- If you were Doug McMillon, president, and CEO of Walmart, what would be your strategic plan to improve Walmart’s supply chain and why?

- Where are the greatest opportunities to improve efficiency?

- How do you think this plan would help Walmart to compete against Amazon?

Not the questions you were looking for? Submit your own questions & get answers .

Walmart: Supply Chain Management Case Answers

1. analyze the walmart supply chain. do you think their capabilities are a competitive advantage for walmart why yes or why not.

According to Barnes (2001), capabilities can be understood as a certain set of business developments that are being understood strategically. Every firm delivers value to its customers through these business developments. Stalk et al. (2015) dispute that a firm’s business processes can be used to achieve a competitive advantage, provided that they are being seen as strategic capabilities. As such, Walmart’s supply chain practices assist in attaining multiple competitive advantages, such as cost-saving strategies and better client service and solutions delivery procedures.

Walmart implemented an ¨everyday low-price¨ (EDLP) strategy as its business model to reduce the costs and investments related to its operations.

Thus, Walmart’s supply chain plays a major role in maintaining this “good-deal” strategy. This strategy consists of the following key practices:

The primary and fundamental reason behind Walmart’s successful competitive advantage relates to the intensive involvement of customers, partners, suppliers, and management.

For instance, Walmart has an excellent and long-term affiliation with its suppliers due to two reasons. Walmart offers suppliers large orders and commits to them for a relatively long time. by using Electronic Data Interchange with its suppliers (EDI).

EDI is a standard format used for exchanging firm documents and making up communication and translation (8th and Walton, 2013). Thanks to this, Walmart creates coordination between suppliers tightly in product delivery schedules, thus minimizing potential risks involved.

Walmart’s second strategy involves utilizing global merchandising centers to acquire merchandise in bulk for lower prices. The company adopts the cross-docking strategy, in which the company avoids the storage of goods during the transportation process.

Instead, the company transfers the products between trucks. Right before the products reach these trucks, the packaging is changed. The tags are being attached to save on the inventory costs and the transportation itself and save on transportation time. This strategy allows Walmart to send unsold products (Black hauls) back to its suppliers, a cost-saving method (Lu, 2018).

Finally, Walmart is the first company to incorporate UPCs (Universal Product Codes) for their transactions to enhance the quality of inventory and supply chain.

The codes will be transferred into a collection of data connected to the global satellite system. Lu (2018) believes that this data collection provides multiple benefits in forecasting the demand and telling the real-time sales from the registers in the stores.

Moreover, thanks to the invention of the RFID (Radio Frequency Identification) tags in shelves, docks, recycled areas, and docks, Walmart managed to save $500 million a year on average. This inventory reduction has made the communication process easier at the same time.

Applying and managing the inventory with the newest technology in distribution methods, for example, the implementation of ¨shelf-scanning¨ robots, etc., will result in a highly efficient supply chain process and a low rate of the ¨bullwhip effect¨.

This occurs when a lack of communication between the supply links causes the inventory to pile up as a reaction to demand ¨spikes¨.

Clayton M. Christensen (2001) provides some insights regarding Walmart’s Supply Chain in his book, ¨The Past and Future of Competitive Advantage¨. He states that ¨competitive advantage is a concept that often inspires in strategists a form of idol worship – a desire to imitate the strategies that make the most successful companies successful¨.

The fact that Walmart was one of the first companies to (successfully) implement data-based decisions regarding their operations processes led to a ¨copycat¨ trigger in other comparable companies, according to Ken Mark (2019). The latter confirms that the capabilities of Walmart are indeed a competitive advantage for the company.

2. How is Walmart managing its supply chain? And compared with their competitors?

Walmart believes in selling merchandise to customers at discounted prices or below standard to gain profit, using developed structure and advanced supply chain management strategies as a competitive strategy. Thus, Walmart has become one of the market leaders and has maintained its status for a long period.

The company applies…

Unlock Case Solution Now!

Get instant access to this case solution with a simple, one-time payment ($24.90).

After purchase:

- You'll be redirected to the full case solution.

- You will receive an access link to the solution via email.

Best decision to get my homework done faster! Michael MBA student, Boston

How do I get access?

Upon purchase, you are forwarded to the full solution and also receive access via email.

Is it safe to pay?

Yes! We use Paypal and Stripe as our secure payment providers of choice.

What is Casehero?

We are the marketplace for case solutions - created by students, for students.

- Continuing Education

- Career Center

- Career Fair

- Certified Analytics Professional

- Pro Bono Analytics

- Analytics Body of Knowledge

- INFORMS Academic Program Database

- Resources for Educators

- Resources for Government Officials

- Resources for Organizations

- Speakers Program

- Student Union

- Video Library

- Annual Meeting

- Analytics Conference

- International Conference

- Healthcare Conference

- Security Conference

- Conference Calendar

- Community Conference Calendar

- Sponsors & Exhibitors

- Past Conferences

- INFORMS Journals

- OR/MS Today

- Analytics Magazine

- OR/MS Tomorrow

- Journal Subscriptions

- INFORMS Analytics Collections

- Member Benefits

- Member Directory

- Self-Service Center

- INFORMS Strategic Plan

- Advertising & Sponsorship Opportunities

- my Communities

- O.R. & Analytics Success Stories

- Walmart: A Grocery Case Study

Optimizing Walmart’s Outbound Supply Chain from Strategy to Execution – A Grocery Case Study

On July 2, 1962, the first Walmart store opened in Rogers, Arkansas, with a strategy to build it on an unshakeable foundation: the lowest prices anytime, anywhere. In the 1980s, the first Walmart Supercenter opened, combining a supermarket with general merchandise; and later in the 1990s, the supercenter model that redefines convenience and one-stop shopping was rolled out nationwide in the U.S. Now in the 21st century, Walmart is expanding the ecosystem that supports customers, enhancing processes that enable them to shop wherever and however they choose, through an omnichannel retailing transformation. At each step of Walmart’s evolution, one of the critical foundations for success is the applications and systems to support supply chain management across the decision tiers from strategy to execution.

Currently for grocery products, customers can choose shopping in store, pickup at curbside, or delivery from store to home. The introduction of new shopping channels significantly changes the demand patterns faced by the 4,700+ brick-and-mortar stores and creates great challenges for its supply chain to meet the demand. Meanwhile, the recent advancements of warehouse automation technologies, especially in the cold-chain space, have unlocked huge potential to revolutionarily improve productivity. There is a more imperative need than ever before to strategically transform the supply chain network at larger scale in a shorter timeframe.

At the execution level, Walmart has a long history of adopting industry leading supply chain optimization technologies to help continuously drive down operational costs. It has reached a point where any incremental cost reduction on standalone systems becomes very challenging. For example, for dry grocery commodities, Walmart’s trucks were nearly fully utilized in terms of weight and space capacities in the year 2021, providing little room for further utilization increases. A breakthrough in optimization technologies is desired to drive continuous improvement.

Walmart identified opportunities in a virtuous circle between network strategy and execution-level optimization technologies. A supply chain network designed for higher efficiency could unlock greater potential of the optimization applications; on the other hand, faster optimization applications can enable more simulation runs, which allow more scenarios to be evaluated, and thus improve the chances for the recommendations to be adopted by executive decision makers. However, it’s not easy to achieve this virtuous cycle, primarily because of two reasons: 1) considering the most granular level of operating costs at strategic planning level makes the problem intractable and 2) optimization applications need to run much faster to evaluate more scenarios.

Compared to general merchandise, the complexities of outbound grocery product distribution, from network design to daily routing and loading execution, are significantly greater, which creates larger room for improvement on efficiency as well as customer and associate experience. Walmart developed models that are applicable to general merchandising products, but scenario building, recommendations, interpretations, and plan execution are generally kept separated primarily because of the critical difference in temperature requirements.

Walmart built and rolled out an outbound routing and loading planning and optimization system named “Load Planner” to solve truck routing and loading problems in one shot. At its core, Walmart developed a metaheuristic-based framework integrating a suit of algorithms, including various neighborhood searches, heuristics, and mixed-integer programming (MIP) models. At each decision step, the best algorithm and parameter settings are selected based on learning from extensive experimentations with historical data. The framework provided the flexibility to add incremental features, as well as high computational efficiencies, which has been a general challenge when solving NP-hard problems. The optimization system was tested and validated in the past couple years, and is proven to outperform the existing application from both computation time and optimality perspectives.

To support the design of future networks, Walmart developed two MIP models. The first determines the optimal long-term end-state network in terms of distribution center (DC) locations, DC capacities, and DC-to-store alignments. The second multistage model creates the transformation roadmap with time steps, and provides concrete recommendations on how and when to initiate different transformative steps to achieve the end-state network. Both models face challenges to scale up when problem sizes are large. We applied heuristics to considerably reduce the problem size without significant loss of quality and enable running tens or even hundreds of scenarios with different input assumptions and risk levels to arrive at a well-informed set of decisions.

In FY23, with the full network rollout of Load Planner, Walmart was able to avoid 72 million pounds of CO2 and save $75 million by avoiding extra miles and truck loads needed. Given the long range of its planning horizon, the direct effects of this network strategy won’t materialize in the short term, so Walmart will measure its benefits primarily based on business adoption. In the same fiscal year, the network strategy and transformation roadmap were approved for implementation, which will require substantial investment planned over the course of the next several years. So far, the program has received approval and funding for construction of three perishable DCs. The future is full of uncertainty and the transformation model enables sensitivity analysis across multiple variables, providing executive leadership with confidence that the strategy and roadmap are sound, regardless of unforeseen changes that may come.

Walmart Supply Chain Management ( Case study)

Walmart has highly effective supply chain management practices that have contributed significantly to its success. It uses procurement strategies like direct sourcing from manufacturers and vendor managed inventory. Logistically, it employs cross-docking and a hub-and-spoke distribution model. Walmart also pioneered the use of IT in supply chain management, developing systems for inventory tracking, replenishment, and collaboration with suppliers. These integrated IT systems and data-driven practices help Walmart maintain low inventory levels while still ensuring high product availability. Read less

Recommended

More related content, what's hot, what's hot ( 20 ), viewers also liked, viewers also liked ( 10 ), similar to walmart supply chain management ( case study), similar to walmart supply chain management ( case study) ( 20 ), recently uploaded, recently uploaded ( 20 ).

- 1. Name: Salah Ud Din Id: 4636 Topic: Walmart Case Study Presented to Sir Adil Adnan Iqra National University Peshawar https://www.facebook.com/salah302

- 2. Contents • About Walmart ………………………………………………………………… 1 • About Case …………………………………………………........................ 2 • Walmart supply chain management ………………………………….. 3 Procurement and Distributions ………………………………………….. 3.1 Bullwhip effects ………………………........... 3.1.2 Vendor Managed Inventory ……………….. 3.1.3 Logistic Management …………………………………………………………. 3.2 Cross Docking …………………………………… 3.2.1 Hub and Spoke …………………………………. 3.2.2 Inventory management ……………………………………………………….. 4 Use of IT in Supply chain ………………………………………………………. 5 Conclusions …………………………………………………………………………… 6

- 3. About Walmart Walmart, an American multinational retail corporation that runs chains of large department and warehouse stores Sam Walton- Founder & Mike duke- current CEO It started with a single store in Rogers, Arkansas in 1962 and has grown to what is now the world's largest and arguably, the most emulated retailer.

- 4. About Walmart Today, Walmart operates over 11,500 stores in 28 countries around the world generating $482.2 billions (2015) with 1.3 millions employees The average profit per hour is $1.8 million 35 million people shop at Walmart everyday, as much as population of Canada 90% Americans live within 15min of a Walmart

- 5. About the case Walmart has envious supply chain management that change the way business is done. This case present how Successfully Walmart manage supply chain and how it is beneficial for Walmart. This case also talks about the best practices by Walmart in the IT integration to ensures efficiency and effectiveness of supply chain.

- 6. How Walmart manage the supply chain? Procurement and distribution Logistic Management Inventory Management

- 7. Procurement and distribution Wal-Mart emphasized the need to reduce purchasing costs and offer the best price to the customer. They spends a significant amount of time meeting vendors and understanding their cost structure. The company directly procured from manufacturers, by passing all intermediaries.

- 8. Procurement And Distribution Bullwhip effect: Occurs when slight demand variability is magnified as information moves back upstream.

- 9. Continued…

- 10. Using EDI for procurement The computer systems of Wal-Mart are connected to those of its suppliers. EDI enabled the suppliers to download purchase orders along with store-to- store sales information relating to their products sold. On receiving information about the sales of various products, the suppliers shipped the required goods to Wal-Mart’s distribution centers. EDI not only save time and made procurement efficient but also reduce the bullwhip effects.

- 11. Share information: Walmart Data warehouse has the capacity of storage of 570 Terabytes Second only to the U.S Government. But all data is useless until it is shared P&G could monitor Wal-Mart’s sales and inventory data, and then use that information to make its own production and shipping plans more efficiently

- 12. Implement an everyday-low-price strategy Promotional sales are a major contributor to the bullwhip effect. To avoid it, successful retailers such as Walmart have adopted the everyday-low-price strategy.

- 13. Vendor managed inventory A means of optimizing Supply Chain performance in which the manufacturer is responsible for maintaining the distributors inventory levels. The manufacturer has access to the distributors inventory data and is responsible for generating purchase orders. Manufacturers generate orders, not distributors or retailers Stocking information is accessed using EDI A first step towards supply chain collaboration Increased speed, reduced errors, and improved service

- 14. Logistic Management Cross Docking Hub and Spoke

- 15. Cross Docking The practice in logistics management of unloading materials from an incoming trailer trucks and directly loading the materials into outbound trucks with little or no storage in between the transfer process. It is also a mechanism to combine goods from two or more different origins into one transport container or vehicle with the same destination.

- 16. Continued… At Wal-Mart’s new distribution centers, P&G’s trucks are unloaded directly to trucks that will head for Wal- Mart Stores. Products are put on the shelf within 4 hours, and are usually sold within 24 hours. The cross docking strategy has helped Wal-Mart to streamline the supply chain from origin point to the final point of sale and it has reduced the handling cost, operating cost and drastically reduce the inventory storage cost. It has also helped them to get products to the final customer faster. Despite this tight delivery schedule, Wal-Mart has 10 days to pay P&G

- 17. Benefits of Cross Docking “Sell the goods before we have to pay.”

- 18. Hub and spoke In the early 1970s, Wal-Mart became one of the first retailing companies in the world to centralize its distribution system, pioneering the retail hub-and- spoke system. Under the system, goods were centrally ordered, assembled at a massive warehouse, known as ‘distribution center’ (hub), from where they were dispatched to the individual stores (spoke).

- 19. Hub and spoke The hub and spoke system enabled Wal-Mart to achieve significant cost advantages by the centralized purchasing of goods in huge quantities.. and distributing them through its own logistics infrastructure to the retail stores spread across the U.S 84 distributions centers in the United State, each serves 150 stores within a 150 mile radius The distribution centers are serviced by more than 3500 company owned trucks. The company hired only experienced drivers who had driven more than 300,000 accident-free miles, with no major traffic violation.

- 20. Inventory Management Wal-Mart invested heavily in IT and communication systems to effectively track sales and merchandise inventories in stores across the country. With the rapid expansion, it was essential to have a good communication system. Hence, Wal-Mart set up its own satellite communication system in 1983.

- 21. Satellite Communication System

- 22. Continued… Wal-Mart was able to reduce unproductive inventory by allowing stores to manage their own stocks, reducing pack sizes across many product categories, and timely price markdowns. Instead of cutting the inventory across the board, Wal-Mart made full use of its IT capabilities to make more inventories available in the case of items that customers wanted most, while reducing the overall inventory levels.

- 23. Use of IT in the Supply Chain The order management and store replenishment of goods were entirely executed with the help of computers through the Point-of-Sales (POS) system. Through this system, it was possible to monitor and track the sales and merchandise stock levels on the store shelves.

- 24. Continued… Employees at the stores had the “Magic Wand,” a hand-held computer which was linked to in-store terminals through a radio frequency network. These helped them to keep track of the inventory in stores, deliveries, and backup merchandise in stock at the distribution centers.

- 25. Voice-base order filling (VOF) System In 1998, Wal-Mart installed a voice-based order filling (VOF) system in all its grocery distribution centers. Each person responsible for order picking was provided with a microphone/speaker headset, connected to the portable (VOF) system that could be worn on waist belt. They were guided by the voice to item locations in the distribution centers.

- 26. Quick replenishment Since the floor area of any Wal-Mart store varied between 40,000 to 200,000 square feet, movement of goods within the store was an important part of logistics operations. Wal-Mart made significant investments in IT to quickly locate and replenish goods at the stores.

- 27. Retail link system In 1991, Wal-Mart had invested approximately $4 billion to build a retail link system. More than 10,000 Wal-Mart retail suppliers used the retail link system to monitor the sales of their goods at stores and replenish inventories.

- 28. Benefits of retail links system As a result lead time was cut to 11 days from 21 days On the hand inventory was reduced by two weeks Sales grew by $8.5 million in six months By 1990’s about 90% of suppliers were doing business through retail link

- 29. CPFR By the mid 1990s, Retail Link had emerged into an Internet-enabled SCM system whose functions were not confined to inventory management alone, but also covered collaborative planning, forecasting and replenishment (CPFR). CPFR is defined as a business practice for business partners to share forecasts and results data through the Internet, in order to reduce inventory costs while at the same time, enhancing product availability across the supply chain.

- 30. Radio Frequency Identification (RFID) Wal-Mart planned to replace bar-code technology with RFID technology. Because of the implementation of RFID, employees were no longer required to physically scan the bar codes of goods entering the stores and distribution centers, saving labor cost and time.

- 31. Benefits from RFID Drastic decrease in stock out situations Lesser labor requirements Decrease in merchandise thefts Real time tracking of consumption patterns Would help enhance JIT inventory management system

- 32. Conclusion: “People think we got big by putting big stores in small towns. Really, we got big by replacing inventory with information.” Sam Walton founder of Walmart

- 33. Hope You Enjoy it

Wal-Mart’s Supply Chain Management Practices

January 8, 2010

Case Study Abstract

The focus of this case study is the supply chain of the world’s largest retailer, Wal-Mart. Wal-Mart in recent years has struggled with its supply chain. The big question is: Will Wal-Mart be able to revive the competitive advantage it had in the past with its efficient supply chain? This case discusses the supply chain management practices of Wal-Mart over the years. A brief of Wal-Mart’s past distribution, logistics and inventory management processes is covered. The use of innovative Information Technology (IT) practices to enable the supply chain is discussed and highlighted. The benefits or competitive advantage Wal-Mart derived over the years from its supply chain management practices is also covered.

Table of Contents

- Introduction – Can Wal-Mart sustain its Supply Chain Advantage?

- Wal-Mart in US Retail Market

- Wal-Mart – Company Background

- Wal-Mart – Timeline

- Wal-Mart: Quick Facts (Revenues, Total Employees and Stores, Competitors, Major Brands/Labels, Business/Growth Strategy)

- MANAGING THE SUPPLY CHAIN – THE WAL-MART WAY

- Pricing and Procurement Strategy

- Supply Chain Integration through Product/Process Knowledge Sharing

- Supply Chain Partnerships

- Distribution Strategy

- Logistics Management

- Cross Docking

- Inventory Management

- Store Formats

- Wal-Mart – International operating formats

- Related Reading

- Questions for discussion

- View sample pages of this case study

Case Study Keywords: Wal-Mart, Supply Chain Management, Retailing Strategy Case Study, Logistics and Distribution, IT enabled supply chain, Information Technology, Supply Chain Partnerships, supply chain integration, information sharing, inventory management, retail store formats, cross docking, pricing and procurement, Sam Walton, discount stores, walmart.com.

Case questions for discussion.

- Wal-Mart’s focus on supply chain management is responsible for its leadership in the retail industry. Discuss the distribution and logistics practices adopted by Wal-Mart. How far has Wal-Mart’s supply chain contributed to its competitive advantage? Explain.

- Companies that have significant buyer power and are very focused on exerting price pressure on their suppliers rather than seeking increased profitability through business process innovations. Support this statement with examples/best practices from your own field.

- Wal-Mart has always used innovative information technology tools to supplement its supply chain. In a few words, explain how use of IT tools/enabled processes have benefited Wal-Mart. How has IT impacted you/your department?

- What steps can Wal-Mart take in order to revive/sustain its supply chain advantage?

- Wal-Mart invited its major suppliers to develop profitable supply chain partnerships. Discuss how good/bad is sharing knowledge/critical information with vendors/suppliers or even customers?

- “It’s not a sale; it’s a great price you can count on every day to make your dollar go further at Wal-Mart.”, as quoted in the article, “Pricing Philosophy,” posted on www.walmart.com. Comment.

Other Case Studies on Wal-Mart

- Organization Culture at Wal-Mart

- Wal-Mart in Japan

- Tesco takes on US Wal-Mart

Case Updates/Snippets

- Wal-Mart’s new slogan – In September 2007, Wal-mart changed its slogan to “Save Money. Live Better.” Wal-Mart’s earlier slogan for 19 years was “Always Low Prices.”

- Benefits of shopping at Wal-Mart – According to a study by research firm Global Insight, Wal-Mart saves American families $2,500 each year. This figure rose from $2,329 in 2004 by 7.3 percent.

- Wal-Mart’s new slogan in 2011 : Wal-Mart’s latest tagline is “Low Prices. Every Day. On Everything.”

- Wal-Mart Online – Wal-Mart has 10,000 stores globally with annual revenues of more than $400 billion and 200 million weekly shoppers. According to Internet Retailer, it ranks six as in the largest Internet retailer list. Wal-Mart trails Amazon.com Inc, Staples Inc, Apple Inc, Dell Inc and Office Depot Inc. Wal-Mart does online business in United States, the UK, Canada and Brazil and does not reveal the percentage of online sales. Its digital technology unit called @WalmartLabs targets smartphones and social networking audience.

MBA Knowledge Base

Business • Management • Technology

Home » Management Case Studies » Case Study: Supply Chain Management of Walmart

Case Study: Supply Chain Management of Walmart

The world’s largest retailer Wal-Mart was founded by Sam Walton in the year 1962. He opened his first store in Rogers, Ark. On 31st October 1969, the company was incorporated as Wal-Mart Stores. Key success factor was the guidance of Sam. Presently they are operating in fifteen countries with more than 8,000 stores with 2.1 million employees (2009). Major features of Wal-Mart stores are its store area, cleanliness and its shelves which is filled with varieties of quality items that includes health care products, family apparels, electronic items, automotive products, hardware items, jewelry etc.

Wal-Mart is giving more emphasis for customer needs and tried to reduce cost through the effective usage of supply chain management system . In the year 2009, Fortune Magazine ranked Wal-Mart as first among other retailers in its survey. Sales were about 401 billion U.S dollars in the FY 2009. Sam Walton claims that Wal-Mart’s vision had always been to increase sales through lowering the costs through organized distribution system with the help of the Information Technology. It is said that Wal-Mart’s extreme success could be attributed to its effective supply chain management.

Wal-Mart’s efficiency in supply chain management was due to two key factors namely automated distribution center and the computerized inventory system. This brought in minimizing a lot of time the later not only reduced the checking out time but also recorded the transaction which is much needed to know envisage demand. Demand forecast is a constant issue which could be a threat when not handled properly. This is due to the fact that demand prediction is always inaccurate. Aggregation would be a remedy for this unpredictable demand.

Wal-Mart’s focus has always been to sell goods at a lower price to the customers. They ensured direct purchase form the companies bypassing the intermediaries. This by passing is one of the ways to reduce cost. Wal-Mart preferred small vendors to the big players however the vendor who provides the best price qualifies and gets the deal. This applies to the giants like P& G as well. Their practice these days had been choosing few vendors and they literally negotiate the best price the one that comes up with the best price qualifies. This does not blindly mean that they have been ruthless. Wal-Mart also work with the vendors for improving its supply chain efficiency.

Wal-Mart with its power distribution system made quite innovative changes like reducing paper work, reduced its lead time drastically, used bar codes to bill which recorded inventory levels and the access to the stock levels served as the valuable data for management. The movements of products are systematic and strategically aliened in a way that it reduces the most valuable time and cost and results in efficiency. Wal-Mart had a very effective rather responsive and flexible distribution system to transport goods from docks to stores. It educated the drives with the ethics and code of conduct which pictures their supply chain responsibility. Cross docking is one lethal weapon that was used by Wal-Mart in their SCM.

Cross Docking: Cross Docking is a method of handling goods. This happens when vendor and the company work together. This is the method of supplying the product in the right time and the said quantity. This cut down a lot of time. This also changed Wal-Mart’s way of looking things. This transitioned Wal-Mart from being a centralized management to almost decentralized system took a major turn in focus of pull strategy than a pull strategy.

Cross-docking is one of the techniques used by Wal-Mart. It means there is no unnecessary storage or little storage in between the loading and unloading of goods so that customer can enjoy the quality of the goods by first hand. Wal-Mart have logistics infrastructure which is very fast transportation system wherein the distribution centers are being serviced. Wal-Mart assured that their drivers are capable of doing their jobs accordingly and do not cause unnecessary delays that can hamper the efficiency of the distribution operations. To deliver it on time, the coordinators give information to the driver the expected time of arrival or delivery of the goods.

Point Of Sale: Information sharing is one of the most important things when it comes to SCM. P&G with its Pampers requested Wal-Mart to share its point of sale so that it could predict its demand more or less and work on the information to bring in efficiency. When Wal-Mart shared this information P&G could plan in advance and it with its efficient supply chain management could supply pampers to Wal-Mart on time.

Wal-Mart did not want to dedicate lot of space to pamper in its warehouse of shop store either. Instead the supply was taken care by P& G. This led the initiation of working with the vendors and coming out with huge efficiency by maintaining lower inventory and satisfying demand without stock outs. Thus point of sale sharing would be a key element for any company for its further scope of improvement and also when there is further scope of improvement there is a role for Supply chain management.

Related Posts:

- Case Study of McDonalds: Advertising and Promotion Strategies

- Case Study of Dell: Primary Target Markets and Positioning Strategy

- Case Study: Zara's Supply Chain Success Story

- Case Study: How Walmart Enhances Supply Chain Management with ERP Initiatives?

- Case Study of Zara: Use of Technology to Improve Operational Responsiveness

- Case Study: Why Walmart Failed in Germany?

- Case Study of Johnson & Johnson: Using a Credo for Business Guidance

- Zara's Lean Operation: Source of Competitive Advantage

- Case Study: The International Growth of Zara

- Case Study of Zara: A Better Fashion Business Model

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Subscribe to AI in Action – your guide to AI adoption in business >

- August 16, 2023

- AI Case Studies

Case Study: Walmart’s AI-Enhanced Supply Chain Operations

Walmart, the world’s largest retailer, has been at the forefront of utilizing innovative technologies to optimize its supply chain management. Its investment in technology spans automation, machine learning, AI-driven chatbots, and leveraging models like GPT-4 to enhance both internal processes and customer experience. The multifaceted approach encompasses not only internal management systems but also reaches into the supplier negotiations, enhancing various dimensions of the business.

Key Takeaways

- The implementation of AI in Walmart’s supply chain management encompasses various aspects including procurement, storage, and distribution, demonstrating a comprehensive approach to leveraging technology.

- By partnering with startups like Pactum, Walmart has begun to utilize AI for contract negotiations, showcasing innovation in non-traditional areas.

- With a strong focus on automation, Walmart has outlined ambitious plans to power 65% of its stores with automation technologies by 2026, a move that reflects the retailer’s forward-thinking strategy.

Deep Dive: Walmart’s AI-Enhanced Supply Chain Operations

Walmart’s approach to implementing AI in its supply chain is comprehensive, focusing on automation, negotiations, procurement, and customer interaction. From investing in Pactum’s negotiation bot to automating 55% of the fulfillment center volume, the approach spans various facets of the supply chain.

Implementation

The implementation of AI has been progressive, with Walmart first starting with Google’s BERT models and then advancing to GPT-4. They are using AI to negotiate contracts with suppliers, as well as for forecasting, procurement, and inventory management. Automation technologies have been rolled out to enhance storing, retrieving, and packing for merchandise. Walmart also employs chatbots for customer care and natural language understanding at a retail-specific level.

Walmart’s AI initiatives have yielded significant results. The chatbot, for instance, negotiated with 68% of suppliers approached, gaining 1.5% in savings and extending payment terms. Automation in supply chain is estimated to improve unit cost averages by around 20%. A notable customer-centric result is the development of platforms like Text to Shop that utilizes natural language understanding to enhance the shopping experience.

Challenges and Barriers

The implementation of AI in supply chain management has not been without challenges. There is a concern about trust and possible erosion of relationships in bot-to-bot negotiations. There is also a need to carefully navigate the “creepiness” of anticipating customer needs too accurately. The rapid change in technology requires Walmart to remain agile to avoid unnecessary technological lock-ins.

Future Outlook

The future for Walmart’s AI in the supply chain looks promising. With plans for more automation and a focus on generative AI for new customer experiences, Walmart is set to continue leading in technological innovation. Opportunities such as the potential creation of a ChatGPT plugin, 3D product generation, and multimodal applications are indicative of an expansive and ambitious future path.

Walmart’s extensive use of AI in its supply chain represents a model for how retail giants can leverage technology for efficiency, customer engagement, and cost savings. The case of Walmart demonstrates both the potential rewards and the inherent challenges of integrating AI into complex business processes. Their willingness to innovate and take calculated risks, coupled with a commitment to ethical implementation, sets a precedent that other businesses may well seek to follow. As technology evolves, so too will Walmart’s strategies, solidifying their position as a leader in using AI to transform the retail landscape.

To get the latest AI case studies straight to your inbox, subscribe to AI in Action by AIX — your weekly newsletter dedicated to the exploration of AI implementation and adoption in business.

Elevate your understanding of AI applications. Browse case studies sorted by company, industry, use case, and technology.

Sources: Multinationals turn to generative AI to manage supply chains Walmart VP confirms retailer is building on GPT-4, says generative AI is ‘as big a shift as mobile’ Negotiating With A Chatbot: A Walmart Procurement Case Study Walmart Accelerates Investment in Supply Chain Technologies

Get in touch

Whether you’re looking for expert guidance on an AI initiative or want to share your AI knowledge with others, our network is the place for you. Let’s work together to build a brighter future powered by AI.

Related Posts

Case Study: AI Integration in IKEA’s Retail Strategy

- April 13, 2024

Case Study: Integration of AI Technologies in 7-Eleven Operations

Case Study: Aldi Leverages AI for Global Efficiency and Sustainability

- Skip to main

- Skip to footer

You're off the clock!

- Flagship Conferences

Decking the aisles with data: How Walmart's AI-powered inventory system brightens the holidays

Parvez Musani

Sr. Vice President, E2E Fulfillment

Oct. 25, 2023

Empowered by our artificial intelligence (AI)-and-machine learning (ML)-driven inventory management systems, Walmart is primed to deliver one of the most seamless and gratifying holiday shopping experiences for our customers. From sought-after gifts and festive decor to delectable treats, our customers and members can be confident in finding the perfect items to make their holiday season merry and bright.

Our AI-powered inventory management system is essential for supplying customers with what they need, when they need it, and at the low costs they expect from Walmart. By leveraging historical data and pairing it with predictive analytics, we’re able to strategically place holiday items across distribution and fulfillment centers, and stores, optimizing the entire shopping experience. This data management system, along with investments in our supply chain—including automated facilities, department-ready freight, Next-Gen fulfillment centers, and store-based fulfillment—combined with in-store technology used by our associates and our massive last-mile delivery network, also ensures the efficient delivery of items. Our system is more powerful because it integrates insights from all the channels we use to serve customers. As an omni-channel retailer, we analyze both physical and digital sales to deliver our customers with an easy shopping experience over the holidays and beyond.

Combining decades of customer service and holiday inventory management with AI insights

Walmart has helped customers and members celebrate the holidays for more than 60 years by continually advancing our inventory management processes to ensure customers can find everything from coveted gifts to festive treats. In recent years, we have tested and integrated AI/ML models into our systems, complementing our use of historical data to guide the flow of holiday items through our supply chain. Today, our AI/ML engines are primed to offer even deeper insights and we expect our performance will be stronger than ever.

When building AI/ML frameworks for holidays, we start with a foundation of data and business constraints to create a possible universe of Machine Learning models. During model training, we fine-tune machine-learning models using historical data like past sales, as well as online searches and page views.

We also consider ‘future data’ such as macroweather patterns, macroeconomic trends and local demographics to anticipate demand and potential fulfillment disruptions. With this combined data, our engines identify and correct discrepancies, inefficiencies, or inaccuracies in supply chain models. By the time our customers are ready to shop, our AI/ML data has already completed the heavy lifting to improve inventory flow.

Leveraging a patent-pending capability

While predicting consumer behavior is possible, unforeseen events and their impact on typical purchasing patterns can create added challenges.

However, we do not always want to apply anomalies like a once-in-a-lifetime snowstorm in Florida to our future inventory management process. Instead, our software aims to display demand as closely as possible to historical consumer tendencies and adjustments.

What makes our AI/ML engines so powerful is that they can ‘forget’ such anomalies so that we are not carrying over one-time deviations into future inventory management practices. This will be the first year this capability has been used to help deliver for our customers during the holiday season.

AI is ‘always on’ and ready to distribute, supply and deliver