Eight Disciplines of Problem Solving (8D)

– Eight Disciplines of Problem Solving –

⇓ Introduction to 8D

⇓ What is 8D

⇓ Why Apply 8D

⇓ When to Apply 8D

⇓ How to Apply 8D

Introduction to Eight Disciplines of Problem Solving (8D)

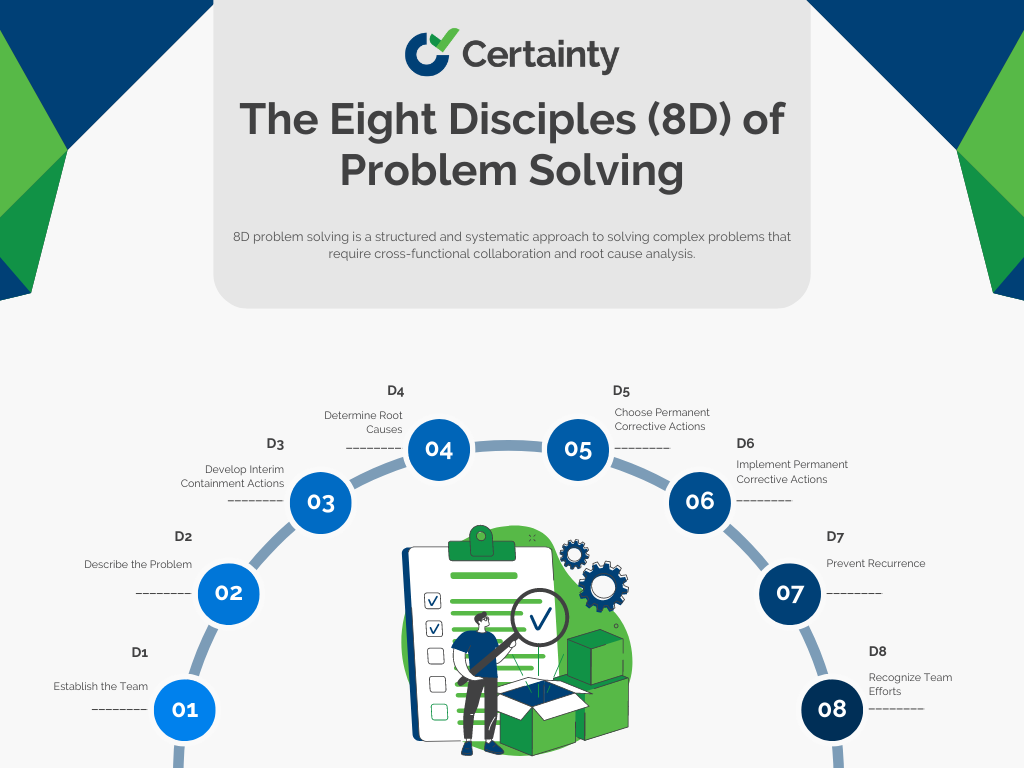

The Eight Disciplines of Problem Solving (8D) is a problem solving methodology designed to find the root cause of a problem, devise a short-term fix and implement a long-term solution to prevent recurring problems. When it’s clear that your product is defective or isn’t satisfying your customers, an 8D is an excellent first step to improving Quality and Reliability.

Ford Motor Company developed this problem solving methodology, then known as Team Oriented Problem Solving (TOPS), in the 1980s. The early usage of 8D proved so effective that it was adopted by Ford as the primary method of documenting problem solving efforts, and the company continues to use 8D today.

8D has become very popular among manufacturers because it is effective and reasonably easy to teach. Below you’ll find the benefits of an 8D, when it is appropriate to perform and how it is performed.

What is Eight Disciplines of Problem Solving (8D)

The 8D problem solving process is a detailed, team oriented approach to solving critical problems in the production process. The goals of this method are to find the root cause of a problem, develop containment actions to protect customers and take corrective action to prevent similar problems in the future.

The strength of the 8D process lies in its structure, discipline and methodology. 8D uses a composite methodology, utilizing best practices from various existing approaches. It is a problem solving method that drives systemic change, improving an entire process in order to avoid not only the problem at hand but also other issues that may stem from a systemic failure.

8D has grown to be one of the most popular problem solving methodologies used for Manufacturing, Assembly and Services around the globe. Read on to learn about the reasons why the Eight Disciplines of Problem Solving may be a good fit for your company.

Why Apply Eight Disciplines of Problem Solving (8D)

The 8D methodology is so popular in part because it offers your engineering team a consistent, easy-to-learn and thorough approach to solving whatever problems might arise at various stages in your production process. When properly applied, you can expect the following benefits:

- Improved team oriented problem solving skills rather than reliance on the individual

- Increased familiarity with a structure for problem solving

- Creation and expansion of a database of past failures and lessons learned to prevent problems in the future

- Better understanding of how to use basic statistical tools required for problem solving

- Improved effectiveness and efficiency at problem solving

- A practical understanding of Root Cause Analysis (RCA)

- Problem solving effort may be adopted into the processes and methods of the organization

- Improved skills for implementing corrective action

- Better ability to identify necessary systemic changes and subsequent inputs for change

- More candid and open communication in problem solving discussion, increasing effectiveness

- An improvement in management’s understanding of problems and problem resolution

8D was created to represent the best practices in problem solving. When performed correctly, this methodology not only improves the Quality and Reliability of your products but also prepares your engineering team for future problems.

When to Apply Eight Disciplines of Problem Solving (8D)

The 8D problem solving process is typically required when:

- Safety or Regulatory issues has been discovered

- Customer complaints are received

- Warranty Concerns have indicated greater-than-expected failure rates

- Internal rejects, waste, scrap, poor performance or test failures are present at unacceptable levels

How to Apply Eight Disciplines of Problem Solving (8D)

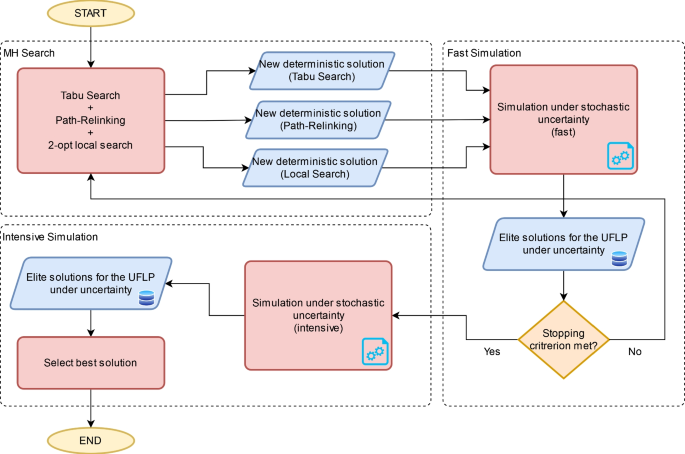

The 8D process alternates inductive and deductive problem solving tools to relentlessly move forward toward a solution. The Quality-One approach uses a core team of three individuals for inductive activities with data driven tools and then a larger Subject Matter Expert (SME) group for the deductive activities through brainstorming, data-gathering and experimentation.

D0: Prepare and Plan for the 8D

Proper planning will always translate to a better start. Thus, before 8D analysis begins, it is always a good idea to ask an expert first for their impressions. After receiving feedback, the following criterion should be applied prior to forming a team:

Collect information on the symptoms

Use a Symptoms Checklist to ask the correct questions

Identify the need for an Emergency Response Action (ERA), which protects the customer from further exposure to the undesired symptoms

D1: Form a Team

A Cross Functional Team (CFT) is made up of members from many disciplines. Quality-One takes this principle one step further by having two levels of CFT:

- The Core Team Structure should involve three people on the respective subjects: product, process and data

- Additional Subject Matter Experts are brought in at various times to assist with brainstorming, data collection and analysis

Teams require proper preparation. Setting the ground rules is paramount. Implementation of disciplines like checklists, forms and techniques will ensure steady progress. 8D must always have two key members: a Leader and a Champion / Sponsor:

- The Leader is the person who knows the 8D process and can lead the team through it (although not always the most knowledgeable about the problem being studied)

- The Champion or Sponsor is the one person who can affect change by agreeing with the findings and can provide final approval on such changes

D2: Describe the Problem

The 8D method’s initial focus is to properly describe the problem utilizing the known data and placing it into specific categories for future comparisons. The “Is” data supports the facts whereas the “Is Not” data does not. As the “Is Not” data is collected, many possible reasons for failure are able to be eliminated. This approach utilizes the following tools:

- Problem Statement

- Affinity Diagram (Deductive tool)

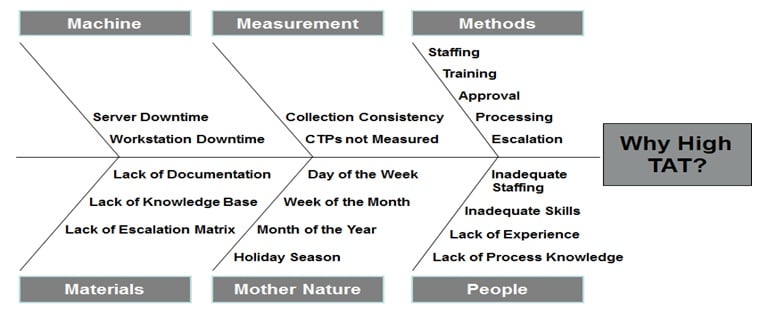

- Fishbone/Ishikawa Diagram (Deductive tool)

- Problem Description

D3: Interim Containment Action

In the interim, before the permanent corrective action has been determined, an action to protect the customer can be taken. The Interim Containment Action (ICA) is temporary and is typically removed after the Permanent Correct Action (PCA) is taken.

- Verification of effectiveness of the ICA is always recommended to prevent any additional customer dissatisfaction calls

D4: Root Cause Analysis (RCA) and Escape Point

The root cause must be identified to take permanent action to eliminate it. The root cause definition requires that it can be turned on or off, at will. Activities in D4 include:

- Comparative Analysis listing differences and changes between “Is” and “Is Not”

- Development of Root Cause Theories based on remaining items

- Verification of the Root Cause through data collection

- Review Process Flow Diagram for location of the root cause

- Determine Escape Point, which is the closest point in the process where the root cause could have been found but was not

D5: Permanent Corrective Action (PCA)

The PCA is directed toward the root cause and removes / changes the conditions of the product or process that was responsible for the problem. Activities in D5 include:

- Establish the Acceptance Criteria which include Mandatory Requirements and Wants

- Perform a Risk Assessment / Failure Mode and Effects Analysis (FMEA) on the PCA choices

- Based on risk assessment, make a balanced choice for PCA

- Select control-point improvement for the Escape Point

- Verification of Effectiveness for both the PCA and the Escape Point are required

D6: Implement and Validate the Permanent Corrective Action

To successfully implement a permanent change, proper planning is essential. A project plan should encompass: communication, steps to complete, measurement of success and lessons learned. Activities in D6 include:

- Develop Project Plan for Implementation

- Communicate the plan to all stakeholders

- Validation of improvements using measurement

D7: Prevent Recurrence

D7 affords the opportunity to preserve and share the knowledge, preventing problems on similar products, processes, locations or families. Updating documents and procedures / work instructions are expected at this step to improve future use. Activities in D7 include:

- Review Similar Products and Processes for problem prevention

- Develop / Update Procedures and Work Instructions for Systems Prevention

- Capture Standard Work / Practice and reuse

- Assure FMEA updates have been completed

- Assure Control Plans have been updated

D8: Closure and Team Celebration

Teams require feedback to allow for satisfactory closure. Recognizing both team and individual efforts and allowing the team to see the previous and new state solidifies the value of the 8D process. Activities in D8 include:

- Archive the 8D Documents for future reference

- Document Lessons Learned on how to make problem solving better

- Before and After Comparison of issue

- Celebrate Successful Completion

8D and Root Cause Analysis (RCA)

The 8D process has Root Cause Analysis (RCA) imbedded within it. All problem solving techniques include RCA within their structure. The steps and techniques within 8D which correspond to Root Cause Analysis are as follows:

- Problem Symptom is quantified and converted to “Object and Defect”

- Problem Symptom is converted to Problem Statement using Repeated Whys

- Possible and Potential Causes are collected using deductive tools (i.e. Fishbone or Affinity Diagram)

- Problem Statement is converted into Problem Description using Is / Is Not

- Problem Description reduces the number of items on the deductive tool (from step 3)

- Comparative Analysis between the Is and Is Not items (note changes and time)

- Root Cause theories are developed from remaining possible causes on deductive tool and coupled with changes from Is / Is Not

- Compare theories with current data and develop experiments for Root Cause Verification

- Test and confirm the Root Causes

Example: Multiple Why Technique

The Multiple / Repeated Why (Similar to 5 Why) is an inductive tool, which means facts are required to proceed to a more detailed level. The steps required to determine problem statement are:

- Problem Symptom is defined as an Object and Defect i.e. “Passenger Injury”

- Why? In every case “SUV’s Roll Over”

- Why? In every case, it was preceded by a “Blown Tire”

- Why? Many explanations may be applied, therefore the team cannot continue with another repeated why past “Blown Tire”

- Therefore, the Problem Statement is “Blown Tire”

- Why? Low (Air) Pressure, Tire Defect (Degradation of an Interface) and High (Ambient) Temperature

- Counter measures assigned to low pressure and tire defect

This example uses only 4 of the 5 Whys to determine the root causes without going further into the systemic reasons that supported the failure. The Repeated Why is one way to depict this failure chain. Fault Tree Analysis (FTA) could also be used.

Learn More About Eight Disciplines of Problem Solving (8D)

Quality-One offers Quality and Reliability Support for Product and Process Development through Consulting, Training and Project Support. Quality-One provides Knowledge, Guidance and Direction in Quality and Reliability activities, tailored to your unique wants, needs and desires. Let us help you Discover the Value of 8D Consulting , 8D Training or 8D Project Support .

Contact Us | Discover the Value!

(248) 280-4800 | [email protected]

Remember Me

- Don't have an account? Register

- Lost your password? Click here

- Already have an account? Log in

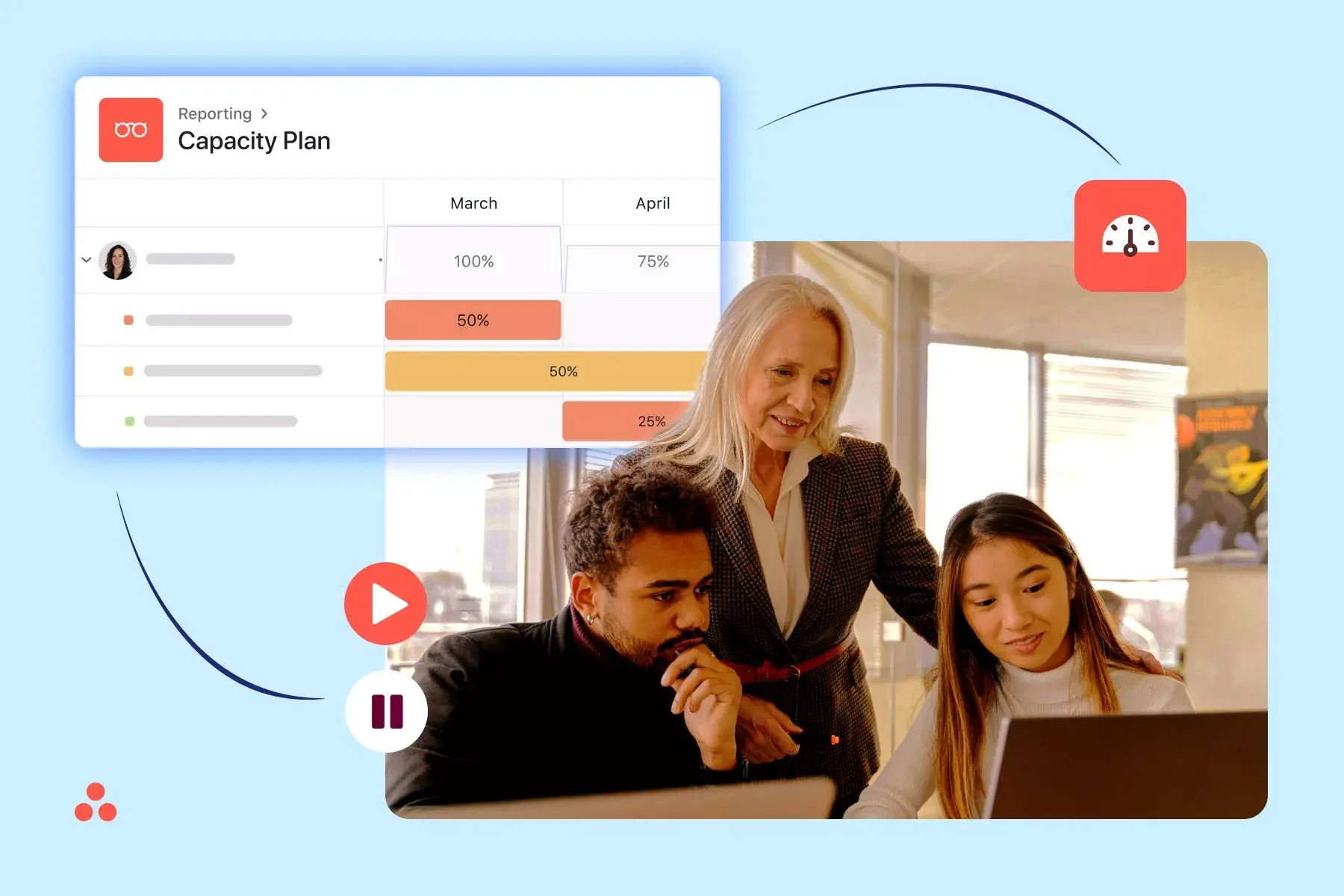

How it works

For Business

Join Mind Tools

Article • 8 min read

8D Problem Solving Process

Solving major problems in a disciplined way.

By the Mind Tools Content Team

(Also known as Global 8D Problem Solving)

When your company runs into a major problem, you need to address it quickly. However, you also need to deal with it thoroughly and ensure that it doesn't recur – and this can take a lot of effort and elapsed time.

The 8D Problem Solving Process helps you do both of these seemingly-contradictory things, in a professional and controlled way. In this article, we'll look at the 8D Problem Solving Process, and we'll discuss how you can use it to help your team solve major problems.

Origins of the Tool

The Ford Motor Company® developed the 8D (8 Disciplines) Problem Solving Process, and published it in their 1987 manual, "Team Oriented Problem Solving (TOPS)." In the mid-90s, Ford added an additional discipline, D0: Plan. The process is now Ford's global standard, and is called Global 8D.

Ford created the 8D Process to help teams deal with quality control and safety issues; develop customized, permanent solutions to problems; and prevent problems from recurring. Although the 8D Process was initially applied in the manufacturing, engineering, and aerospace industries, it's useful and relevant in any industry.

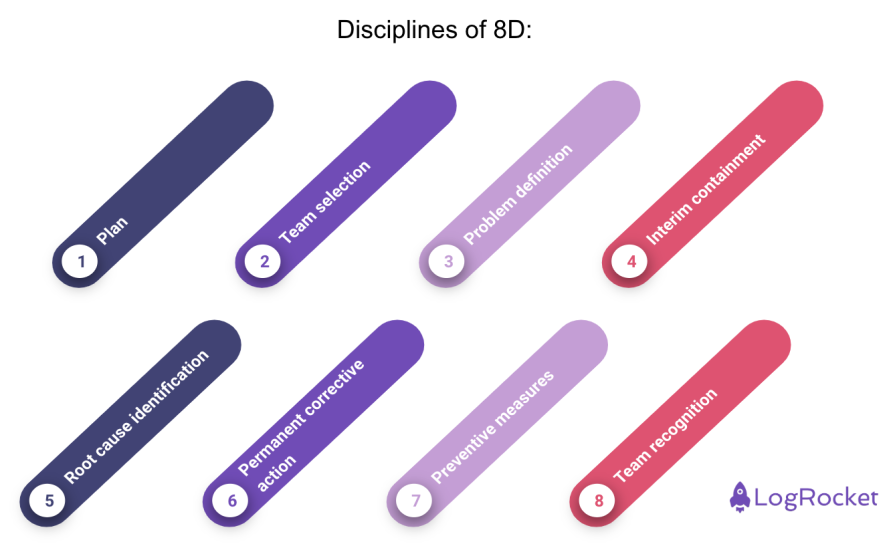

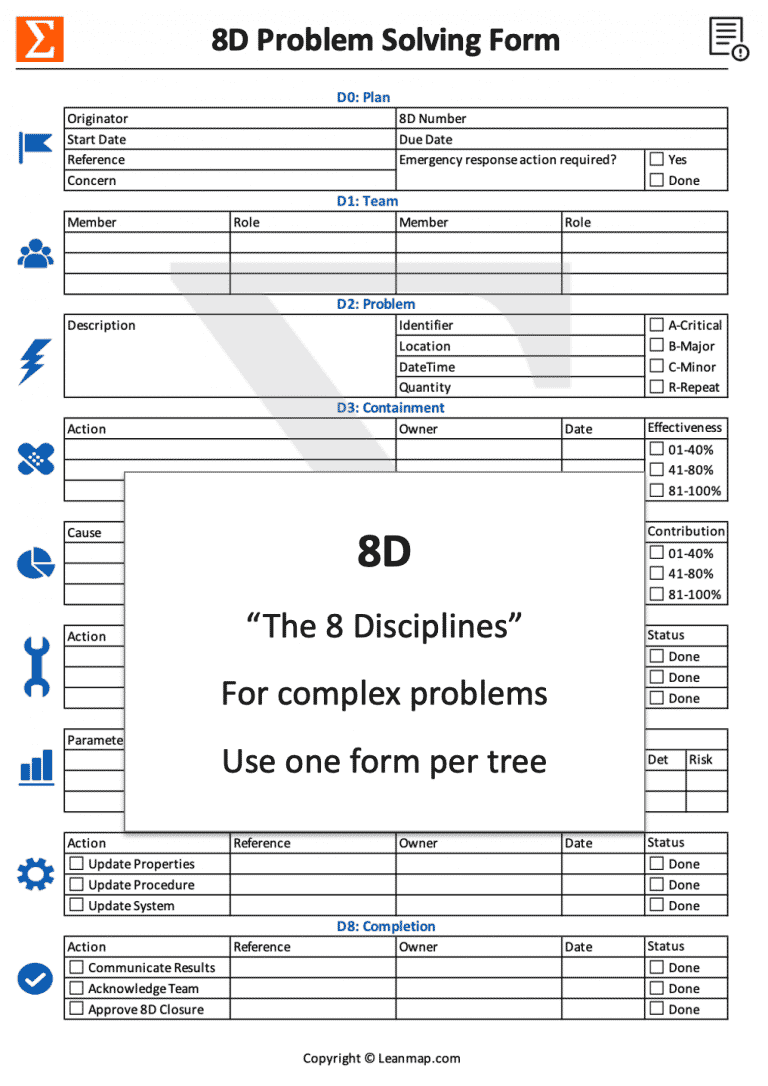

The eight disciplines are shown in figure 1, below:

Figure 1: The 8D Problem Solving Process

The 8D Process works best in teams tasked with solving a complex problem with identifiable symptoms. However, you can also use this process on an individual level, as well.

Applying the Tool

To use the 8D Process, address each of the disciplines listed below, in order. Take care not to skip steps, even when time is limited; the process is only effective when you follow every step.

Discipline 0: Plan

Before you begin to assemble a team to address the problem, you need to plan your approach. This means thinking about who will be on the team, what your time frame is, and what resources you'll need to address the problem at hand.

Discipline 1: Build the Team

You should aim to put together a team that has the skills needed to solve the problem, and that has the time and energy to commit to the problem solving process.

Keep in mind that a diverse team is more likely to find a creative solution than a team of people with the same outlook (although if outlooks are too diverse, people can spend so much time disagreeing that nothing gets done).

Create a team charter that outlines the team's goal and identifies each person's role. Then, do what you can to build trust and get everyone involved in the process that's about to happen.

If your team is made up of professionals who haven't worked together before, consider beginning with team-building activities to ensure that everyone is comfortable working with one another.

Discipline 2: Describe the Problem

Once your team has settled in, describe the problem in detail. Specify the who, what, when, where, why, how, and how many; and use techniques like CATWOE and the Problem-Definition Process to ensure that you're focusing on the right problem.

Start by doing a Risk Analysis – if the problem is causing serious risks, for example, to people's health or life, then you need to take appropriate action. (This may include stopping people using a product or process until the problem is resolved.)

If the problem is with a process, use a Flow Chart , Swim Lane Diagram , or Storyboard to map each step out; these tools will help your team members understand how the process works, and, later on, think about how they can best fix it.

Discovering the root cause of the problem comes later in the process, so don't spend time on this here. Right now, your goal is to look at what's going wrong and to make sure that your team understands the full extent of the problem.

Discipline 3: Implement a Temporary Fix

Once your team understands the problem, come up with a temporary fix. This is particularly important if the problem is affecting customers, reducing product quality, or slowing down work processes.

Harness the knowledge of everyone on the team. To ensure that each person's ideas are heard, consider using brainstorming techniques such as Round Robin Brainstorming or Crawford's Slip Writing Method , alongside more traditional team problem solving discussions.

Once the group has identified possible temporary fixes, address issues such as cost, implementation time, and relevancy. The short-term solution should be quick, easy to implement, and worth the effort.

Discipline 4: Identify and Eliminate the Root Cause

Once your temporary fix is in place, it's time to discover the root cause of the problem.

Conduct a Cause and Effect Analysis to identify the likely causes of the problem. This tool is useful because it helps you uncover many possible causes, and it can highlight other problems that you might not have been aware of. Next, apply Root Cause Analysis to find the root causes of the problems you've identified.

Once you identify the source of the problem, develop several permanent solutions to it.

If your team members are having trouble coming up with viable permanent solutions, use the Straw Man Concept to generate prototype solutions that you can then discuss, tear apart, and rebuild into stronger solutions.

Discipline 5: Verify the Solution

Once your team agrees on a permanent solution, make sure that you test it thoroughly before you fully implement it, in the next step.

- Conducting a Failure Mode and Effects Analysis (FMEA) to spot any potential problems.

- Using Impact Analysis to make sure that there will be no unexpected future consequences.

- Using Six Thinking Hats to examine the fix from several different emotional perspectives.

Last, conduct a Blind Spot Analysis to confirm that you and your team haven't overlooked a key factor, or made an incorrect assumption about this solution.

Discipline 6: Implement a Permanent Solution

Once your team reaches a consensus on the solution, roll your fix out. Monitor this new solution closely for an appropriate period of time to make sure that it's working correctly, and ensure that there are no unexpected side effects.

Discipline 7: Prevent the Problem From Recurring

When you're sure that the permanent solution has solved the problem, gather your team together again to identify how you'll prevent the problem from recurring in the future.

You might need to update your organization's standards, policies, procedures, or training manual to reflect the new fix. You'll likely also need to train others on the new process or standard. Finally, you'll need to consider whether to change your management practices or procedures to prevent a recurrence.

Discipline 8: Celebrate Team Success

The last step in the process is to celebrate and reward your team's success . Say "thank you" to everyone involved, and be specific about how each person's hard work has made a difference. If appropriate, plan a party or celebration to communicate your appreciation.

Before the team disbands, conduct a Post-Implementation Review to analyze whether your solution is working as you thought, and to improve the way that you solve problems in the future.

In the late 1980s, Ford Motor Company developed the 8D (8 Disciplines) Problem Solving Process to help manufacturing and engineering teams diagnose, treat, and eliminate quality problems. However, teams in any industry can use this problem solving process.

The eight disciplines are:

- Build the Team.

- Describe the Problem.

- Implement a Temporary Fix.

- Identify and Eliminate the Root Cause.

- Verify the Solution.

- Implement a Permanent Solution.

- Prevent the Problem From Recurring.

- Celebrate Team Success.

The 8D Problem Solving Process is best used with a team solving complex problems; however, individuals can also use it to solve problems on their own.

Ford is a registered trademark of the Ford Motor Company: https://www.ford.com/

You've accessed 1 of your 2 free resources.

Get unlimited access

Discover more content

A Creative Tool That Encourages Participants to Use Different Levels of Thinking

Expert Interviews

The Leader as a Mensch

Bruna Martinuzzi

Add comment

Comments (0)

Be the first to comment!

Try Mind Tools for FREE

Get unlimited access to all our career-boosting content and member benefits with our 7-day free trial.

Sign-up to our newsletter

Subscribing to the Mind Tools newsletter will keep you up-to-date with our latest updates and newest resources.

Subscribe now

Business Skills

Personal Development

Leadership and Management

Member Extras

Most Popular

Newest Releases

What Is Gibbs' Reflective Cycle?

Team Briefings

Mind Tools Store

About Mind Tools Content

Discover something new today

Onboarding with steps.

Helping New Employees to Thrive

NEW! Pain Points Podcast - Perfectionism

Why Am I Such a Perfectionist?

How Emotionally Intelligent Are You?

Boosting Your People Skills

Self-Assessment

What's Your Leadership Style?

Learn About the Strengths and Weaknesses of the Way You Like to Lead

Recommended for you

The demand-control model of job stress.

Increasing Autonomy to Combat Stress

Business Operations and Process Management

Strategy Tools

Customer Service

Business Ethics and Values

Handling Information and Data

Project Management

Knowledge Management

Self-Development and Goal Setting

Time Management

Presentation Skills

Learning Skills

Career Skills

Communication Skills

Negotiation, Persuasion and Influence

Working With Others

Difficult Conversations

Creativity Tools

Self-Management

Work-Life Balance

Stress Management and Wellbeing

Coaching and Mentoring

Change Management

Team Management

Managing Conflict

Delegation and Empowerment

Performance Management

Leadership Skills

Developing Your Team

Talent Management

Problem Solving

Decision Making

Member Podcast

- Guide: 8D Problem Solving

Daniel Croft

Daniel Croft is an experienced continuous improvement manager with a Lean Six Sigma Black Belt and a Bachelor's degree in Business Management. With more than ten years of experience applying his skills across various industries, Daniel specializes in optimizing processes and improving efficiency. His approach combines practical experience with a deep understanding of business fundamentals to drive meaningful change.

- Last Updated: June 13, 2023

- Learn Lean Sigma

8D Problem Solving is a systematic and structured approach used to solve business related problems. It names has been given by the fact there are 8 steps or 8 disciplines that are followed to identify, correct and eliminate recurring problems.

8D Problem Solving is regarded as robust methodology that has proven its worth across multiple industries and manufacturing in particular. The methodology was Initially developed within the automotive industry, it has since been widely adopted in manufacturing, logistics and health care to name a few. The 8D approach goes beyond helping team just identify the root cause of problem but also provides a structured approach for implementing and verifying corrective actions.

Table of Contents

What is 8d problem solving.

The 8D Problem-Solving methodology was developed in the late 1980s by Ford Motor Company. The term “8D” stands for “Eight Disciplines,” which represent the eight critical steps in problem-solving.

Initially it was only intended to resolve issues within the automotive manufacturing process. However, over the year since then the methodology has gained universal acceptance and is now applied across various sectors. The 8D approach was heavily influenced by quality management systems like Total Quality Management (TQM) and methodologies like Six Sigma and forms a key part of quality roles and Six sigma qualifications.

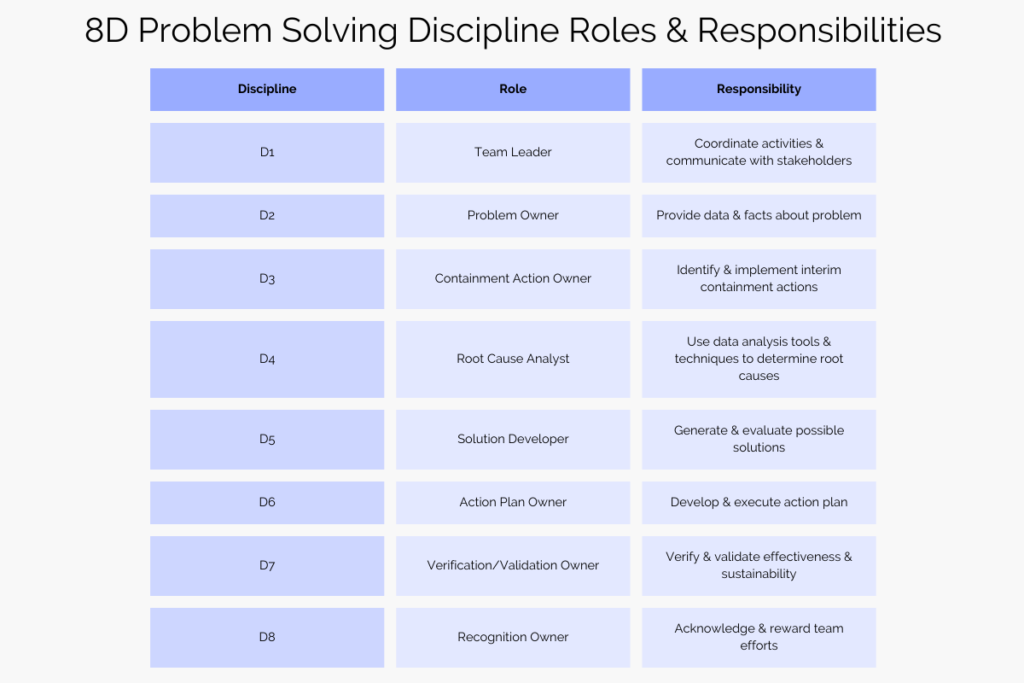

8D is also encourages collaborative team based approach to addressing issues in the workplace This methodology was purposefully designed to be a cross-functional effort, ensuring to bring together expertise from different departments or disciplines to comprehensively address an issue by looking at it from all point of view. Here are the key components:

Preparation : Before diving into problem-solving, the team gathers all necessary resources and tools.

Team Establishment : A cross-functional team is assembled, each member having a specific role and responsibility.

Problem Description : The issue at hand is clearly defined to ensure everyone has a shared understanding.

Interim Actions : Short-term solutions are implemented to contain the problem and prevent further damage.

Root Cause Analysis : Various tools and methods are used to identify the real cause of the problem.

Permanent Corrective Actions : Long-term solutions are selected and verified to eliminate the root cause.

Implementation : The long-term solutions are implemented across the board, including necessary changes to policies and procedures.

Prevent Recurrence : Measures are taken to ensure that the problem does not occur again.

Team Recognition : The team is congratulated and acknowledged for their efforts.

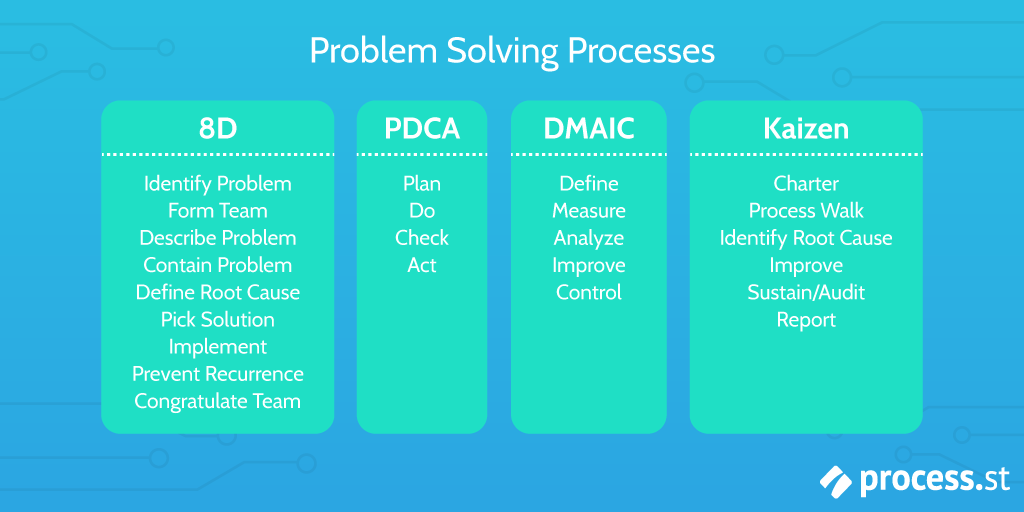

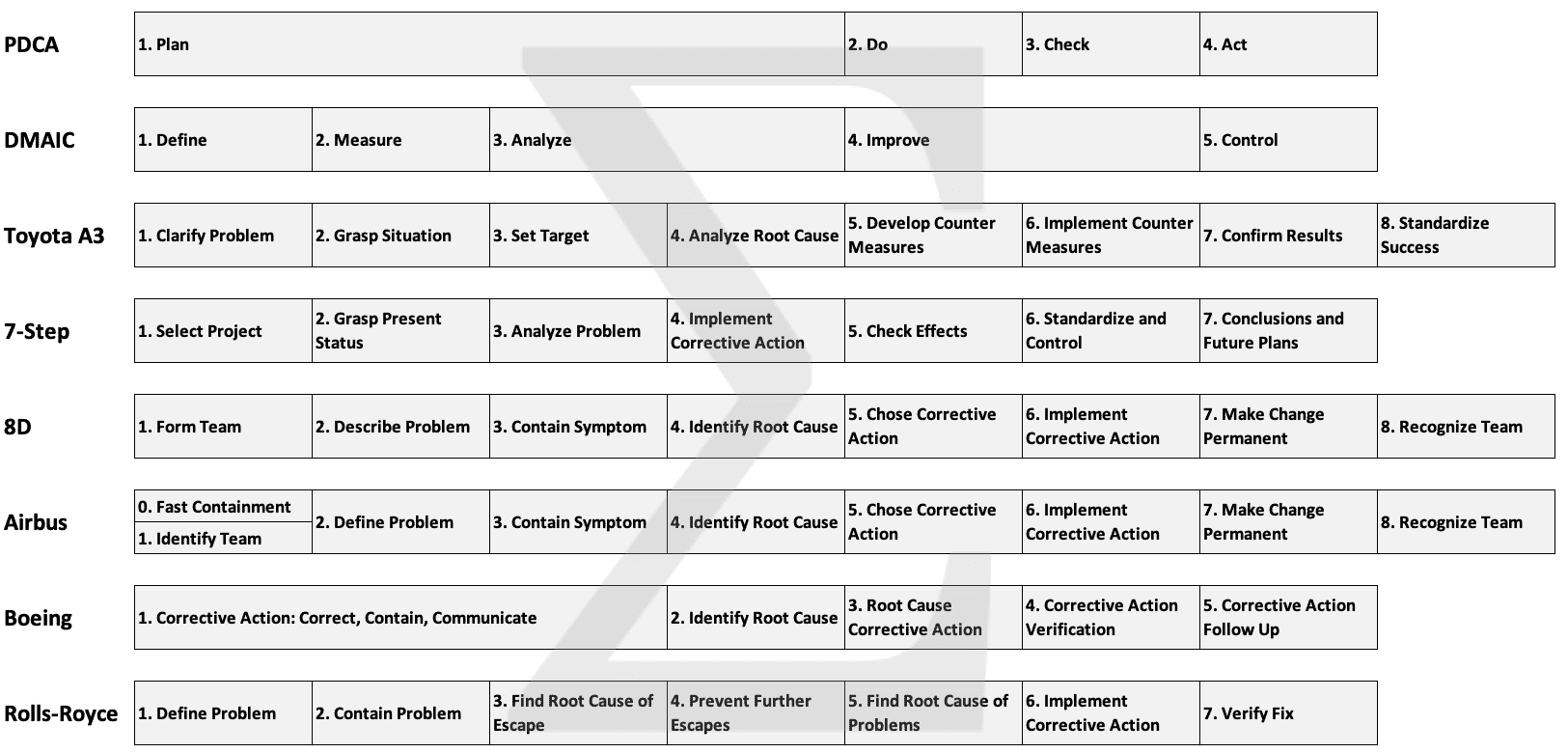

How does 8D Compare to over Problem-Solving Methods?

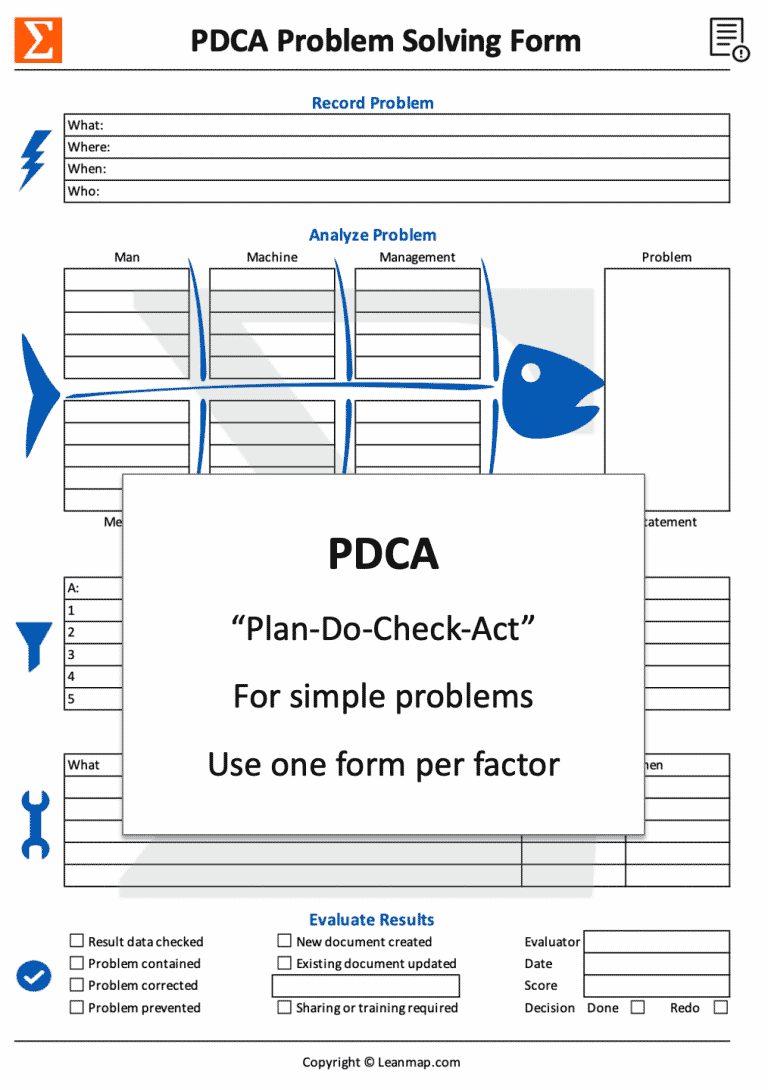

Between quality management systems and lean six sigma there are several problem-solving methodologies such as PDCA (Plan-Do-Check-Act), DMAIC (Define-Measure-Analyze-Improve-Control), and A3 . However the combination of the 8D steps results in a comprehensive frame work that is:

Team-Oriented : Unlike some methodologies that can be carried out by individuals, 8D strongly emphasizes team collaboration as a core principle as seen in steps D1 and D8.

Structured Framework : 8D provides a very detailed, step-by-step guide for solving complex problems, by breaking it down in to logical steps making it easier to manage and track progress.

Broad Applicability : While some methodologies like DMAIC are closely tied to Six Sigma, 8D can be applied in various contexts without being tied to a particular quality management system.

Focus on Prevention : 8D not only aims to solve the problem but also focuses on implementing changes to prevent its recurrence, making it a complete approach to problem solving.

The 8 Disciplines Explained

D0: prepare for the process.

Before you start 8D you should prepare for the 8D process. This phase sets the foundation for the entire methodology, ensuring that the team is able to tackle the problem effectively. Therefore, effective preparation helps in avoiding unnecessary delays and ensures that you’re not solving the wrong problem.

Within the initial preparation step you should also the time to think about what knowledge, expertise and experience you need within the team. Cross-functional teams are important, as they bring alternative perspectives and skills to the table rather than everyone looking at the problem from one point of view. Make sure you consider expertise, availability, and interest when selecting team members.

D1: Establish the Team

In D1 you should establish the team by clearly defining the roles and responsibilities for each team member. This includes assigning a team leader, subject matter experts, and roles for data collection , analysis, and communication this helps to provide the team members clarity on how they will be involved and contribute to the success of the problems solving activity.

Team Composition

Once roles are defined, where possible ensure that the team is balanced in terms of skills and expertise. A well-rounded team will be more effective in tackling various aspects of the problem.

Communication

Establish clear methods communication, both within the team and with external stakeholders. Such as deciding on regular meeting schedules that everyone can attend, reporting formats, and tools for collaboration.

D2: Describe the Problem

In D2 it is time to create a well formed problem statement. This step is key as it provides a foundation for understanding the problem which will lead to generally more successful problem-solving. It ensures that everyone clearly understands what needs to be addressed, setting the scope for the entire process. Ensure that the problem is clearly understood by everyone in the team at this stage to prevent confusion later on in the process.

5W1H Method of creating a Problem Definition

Use data gathering techniques such as observations, interviews, and document reviews can help to precisely identify the problem. A useful tool to use at this stage could be the 5W1H Problem definition method.

You can find out more about this method with our 5W1H guide .

Problem Definition – is / is not template

When creating your problem definition ensure to be specific, measurable, and unambiguous when stating the problem. You should avoid generalities and ensure that the problem statement is understandable to someone unfamiliar with the issue. If you are new to this process it may be helpful to give the statement to someone unfamiliar to the process and see if they understand it or if they have questions. You can then clarify any questions by adjusting the problem description to improve the claity.

D3: Implement and Verify Interim Actions

In D3 while the team is investigating the root cause, interim actions are must be implement to contain the problem and minimize its impact. This is particularly important in critical situations affecting safety, compliance, or customer satisfaction.

In this step you should identify, plan, and execute short-term fixes that can quickly contain the problem. This could include quarantining the product to ensure it is not sent out to the customer or even pausing production lines that continue to product defects. Ensure these actions are documented for future reference.

Use metrics and KPIs to gauge the effectiveness of the interim actions. Make adjustments as necessary.

D4: Root Cause Analysis

D4 is where you start to understand what is causing the issue by identifying the underlying reason for the problem. The objective is to find the root cause, not just the symptoms.

At this stage there are a range of quality and lean six sigma tools that can be used to conduct root cause analysis , which can include the Fishbone Diagram for structured brainstorming and the 5 Whys technique for causal chain analysis.

We have a range of guides on all of these techniques for you to use.

Once identified, it is important validate the root cause through experimentation or additional data analysis to ensure it’s the actual cause and not a symptom, this can often be an overlook critical step in the root cause process.

D5: Choose and Verify Permanent Corrective Actions

In D5 you need to choose what actions to be taken to prevent the problem reoccurring and any solutions implemented should be verified that the actions correct the problem this can involve trial runs, further data collection and inspections of product or services being produced.

You should also consider factors like cost, impact, and feasibility when choosing a permanent corrective action and should also conduct a risk assessment to evaluate potential negative outcomes of the actions taken

An implementation or action plan is often useful to document at this stage to detail the steps for implementation, assign responsibilities, and set timelines.

D6: Implement Permanent Corrective Actions

Once verified, implement the corrective actions across all relevant departments or processes. This can involved documenting the new process and training out to all stakeholders involved to ensure the new process is followed and that the stakeholders understand the reason for the change.

At this point you should continue to regularly monitor the situation to ensure the corrective actions are sustained and effective, this could be for a period of 30, 60 or 90 days after the problem was resolved to ensure the new process has become a sustained and issues do not reoccur.

D7: Prevent Recurrence

In D7 to prevent recurrent you should review and update organizational policies or standard operating procedures (SOPs) to prevent a recurrence of the problem and document the new standard process

It is important to conduct regular reviews to continuously monitor the process and ensure procedures are being followed but also to identify further opportunities for process improvement.

D8: Congratulate the Team

The final step D8, after the hard work and successful problem resolution, it is important to acknowledging and congratulating the team is vital for morale and future engagement. With the recognition of a successful 8D Problem-solving activity complete you are more likely to encourage future participation as the method gets a reputation as being useful and successful at solving problems.

Whether it’s a team lunch, certificates of achievement, or simply a public acknowledgment, celebrate the success in a way that resonates with your team.

Finally it is always important to conduct a lessons-learned session and document the insights gained during the process for future reference. This can be used as a future point of reference for problem solving activities.

Mastering the art of problem-solving is crucial in today’s complex and fast-paced environment. The 8D Problem-Solving methodology offers a structured, team-based approach to tackling challenges that can arise in any sector, be it manufacturing, public services, or logistics. This guide has walked you through each of the eight disciplines, offering best practices and highlighting common pitfalls to avoid. We’ve also enriched your understanding through real-world case studies that demonstrate the methodology’s versatility and effectiveness. Remember, the strength of 8D lies not just in identifying and resolving problems, but also in preventing their recurrence through systemic improvements. By adhering to the principles and steps outlined in this guide, you’re well on your way to becoming an adept problem solver, capable of driving continuous improvement in your organization.

- Zarghami, A. and Benbow, D.W., 2017. Introduction to 8D problem solving . Quality Press.

- Camarillo, A., Ríos, J. and Althoff, K.D., 2017. CBR and PLM applied to diagnosis and technical support during problem solving in the Continuous Improvement Process of manufacturing plants . Procedia Manufacturing , 13 , pp.987-994.

Q: What is 8D problem solving?

A: 8D problem solving is a systematic approach used to address and resolve complex problems. It is widely utilized in various industries to identify the root causes of issues, develop effective solutions, and prevent their recurrence.

Q: Why is it called "8D" problem solving?

A: The name “8D” refers to the eight disciplines or steps involved in the problem-solving process. Each discipline represents a specific stage in the methodology, allowing for a structured and comprehensive approach to problem resolution.

Q: What are the eight disciplines (8D) in problem solving?

A: The eight disciplines in problem solving, often abbreviated as 8D, are as follows:

- D1: Form a team

- D2: Define the problem

- D3: Implement containment actions

- D4: Determine the root cause

- D5: Develop and implement corrective actions

- D6: Validate the effectiveness of corrective actions

- D7: Prevent recurrence

- D8: Congratulate the team

Q: What is the purpose of forming a team in the 8D problem-solving process?

A: Forming a team at the beginning of the 8D problem-solving process helps ensure that the right individuals with the necessary expertise are involved in addressing the problem. The team collaboratively works towards understanding the issue, analyzing data, and developing effective solutions.

Q: How is the root cause determined in the 8D problem-solving process?

A: Determining the root cause (D4) involves conducting a thorough analysis of the problem. Various tools and techniques, such as cause-and-effect diagrams, 5 Whys, and data analysis, are employed to identify the underlying factors contributing to the problem.

Q: Can the 8D problem-solving methodology be applied to any type of problem?

A: Yes, the 8D problem-solving methodology is a versatile approach that can be applied to various types of problems across different industries. It provides a structured framework for problem resolution and can be tailored to suit the specific needs and requirements of different situations.

Daniel Croft is a seasoned continuous improvement manager with a Black Belt in Lean Six Sigma. With over 10 years of real-world application experience across diverse sectors, Daniel has a passion for optimizing processes and fostering a culture of efficiency. He's not just a practitioner but also an avid learner, constantly seeking to expand his knowledge. Outside of his professional life, Daniel has a keen Investing, statistics and knowledge-sharing, which led him to create the website learnleansigma.com, a platform dedicated to Lean Six Sigma and process improvement insights.

Download Template

Free lean six sigma templates.

Improve your Lean Six Sigma projects with our free templates. They're designed to make implementation and management easier, helping you achieve better results.

Other Guides

8D Problem Solving: Comprehensive Breakdown and Practical Applications

The 8D problem-solving process stands as a beacon of structured analysis and corrective action within the complexities of operational pitfalls and quality control discrepancies across industries. Originating from the automotive industry and since adopted widely, the methodology offers a meticulous step-by-step approach that fosters team cohesion, addresses problems at their roots, and implements sustainable solutions.

This article seeks to delve into the nuances of the 8D problem-solving framework, presenting a lucid exposition of its origins, a detailed foray into each step enriched by practical examples, and concluding with the unequivocal benefit bouquet it presents to the organization adopting it.

The Origins of the 8D Problem Solving Methodology

The 8D, or "Eight Disciplines," problem-solving approach germinated from the fertile grounds of collaborative efforts to ensure superior quality and reliability in manufacturing. Initially developed by the Ford Motor Company in the 1980s, this systematic method was a response to a confluence of quality and operational issues that were pervasive in the automotive industry. It drew broader appeal as its efficacy became apparent - functioning as an amalgam of logic, analytics, and teamwork to tackle problems methodically.

The wide reach of the 8D methodology is evident in industries ranging from manufacturing to healthcare, aerospace to IT, and beyond. Its universal applicability stems from a foundational adherence to principle over process, transcending the intricacies of industry-specific challenges. By combining reactive and proactive measures, the 8D method helps in not just extinguishing the fire, but also preventing its outbreak, making it an enduring asset in the organizational toolkit.

The 8 Steps of Problem Solving

An incursion into the 8D methodology reveals a framework that is both systematic and flexible. Each step is sequenced to ensure that issues are not merely patched but genuinely resolved, implementing robust preventive measures to curtail recurrences. This section expounds on each disciplinary step and serves as a substrate for practical implementation examples, supplementing theoretical insights with real-world applicability.

Step 1: Establish a Team

The cornerstone of any formidable 8D approach begins with assembling a competent team. The wisdom embedded in this initial phase is the recognition that effective problem-solving is not a solitary venture but a collaborative pursuit. A multidisciplinary team brings diverse perspectives that are critical in diagnosing issues accurately and devising solutions effectively.

When determining team composition, the emphasis should be on a mix of skills and expertise relevant to the problem at hand. Roles within the team should be clearly defined to streamline activities and foster accountability. Each member should be well-versed in their responsibilities, from those leading the problem-solving charge to those executing and tracking actions.

Step 2: Describe the Problem

Clarity is vital in the second step, which necessitates delineating the problem with precision. A meticulous description sets the foundation for targeted analysis and actionable solutions. It involves accruing information that is factual, quantifiable, and devoid of assumptions – the cornerstone of an accurate problem portrayal.

Techniques like '5W2H' (who, what, when, where, why, how, how much) can galvanize teams into crafting detailed problem descriptions. An exemplar of a well-articulated problem statement might state, "Machine X has experienced a 15% decline in output quality, resulting in a monthly loss of 200 units of product Y since January due to recurrent mechanical inaccuracies."

Step 3: Develop Interim Containment Actions

Addressing a problem's immediate impact is pivotal to prevent exacerbation as a root cause analysis is conducted. Interim containment actions can be likened to first aid – essential, though not the definitive cure. These measures should be rigorously designed to quell the problem's spread or intensification without creating new issues.

An interim action for the aforementioned issue with Machine X could involve adjusting the production schedule to mitigate output loss while the machine is under examination. This demonstrates a temperate solution, buying time for a comprehensive fix without severely disrupting the production chain.

Step 4: Define and Verify the Root Cause(s)

Singular in its focus yet pluralistic in its approach, this phase is committed to uncovering the underlying reasons for the problem. Root cause identification is a task of surgical precision, necessitating a deep dive into the problem without the constraints of predetermined notions.

Techniques such as the "5 Whys" and "Fishbone Diagram" guide problem solvers through a structured investigation of potential causes. Verification is as crucial as identification, ensuring that purported root causes stand up to scrutiny and testing.

Step 5: Verify Permanent Corrective Action(s)

Once root causes have been established, attention shifts to devising and validating long-term corrective actions. This step traverses the path from theory to practice. It requires a judicious appraisal of potential solutions with a clear-eyed view of their feasibility, effectiveness, and sustainability.

Best practices in this step incorporate piloting solutions on a smaller scale, enabling refinement before full-scale implementation. A well-considered corrective action for Machine X might involve upgrading mechanical components identified as failure points, subject to cost-benefit analysis and potential disruption to the production line.

Step 6: Implementing and Validating Permanent Corrective Actions

This step transitions the plan into reality, pushing the corrective actions beyond the threshold into the operational environment. Careful implementation is the linchpin, with detailed plans and schedules ensuring that actions are well-executed and efficacious.

The validation process is a keystone in affirming that corrective actions deliver the intended improvements. For Machine X, this could entail monitoring post-repair performance metrics over a defined period against pre-issue levels to authenticate the efficacy of the improvements.

Step 7: Preventive Measures

Armed with insights gleaned, the 7th step propels the methodology into preventative mode. Here, the onus is on forestalling a problem’s resurgence by ingraining the lessons learned into the organizational fabric. The aim is to encapsulate these insights in policies, procedures, or system changes.

This could mean revising maintenance schedules or worker training programs for Machine X to include the specific nuances that led to the mechanical inaccuracies, thereby shielding against repeat episodes.

Step 8: Congratulate Your Team

The final step encompasses a human-centered focus on recognition and commendation. Acknowledgment of the team’s efforts reinforces motivation, fosters a positive culture, and encourages engagement in future problem-solving initiatives.

Celebrating the success could manifest in a ceremonious recognition of the team’s achievements, an internal announcement of their contributions, or a tangible expression of appreciation. This not only cements the accomplishment but also propels a sense of camaraderie and collective purpose.

The Importance of the 8D Problem Solving Process

A mature consideration of the 8D problem-solving process corroborates its contributory significance in unraveling complex issues and instituting consequential improvements. The benefits it confers are manifest in enhanced product quality, heightened customer satisfaction, and the stimulation of a proactive problem-solving culture. Challenges do persist, mainly in the form of resistance to change or insufficient training; nevertheless, with a conscientious implementation, these can be navigated.

Moreover, the 8D approach aligns seamlessly with the pursuit of continuous improvement – a cornerstone of many business philosophies such as Lean and Six Sigma. It thus serves not only as a solution framework but also as a catalyst for organizational growth and learning.

In summary, the 8D problem-solving methodology stands out for its disciplined, team-driven, and methodical approach to tackling complex problems. From its historical roots in the automotive industry to its implementation in modern enterprises, its efficacy in achieving sustainable solutions is undoubted. Online certificate programs and problem-solving courses often feature 8D due to its relevance and value across industries.

As this article delineates each step, with practical applications and advice, the message is clear: mastery of 8D is not just for immediate problem resolution – it is a pathway to building a resilient and adaptive organization capable of facing the challenges of an ever-changing business landscape.

What are the key steps involved in the 8D Problem Solving process and how do they interact with each other?

Introduction to the 8d process.

The 8D Problem Solving process stands tall. It is a structured approach. Businesses use it widely. 8D tackles complex problems effectively. It drives teams towards lasting solutions. It also fosters quality and reliability. The "D" denotes eight disciplined steps. These steps guide teams. They identify, correct, and prevent issues.

8D Steps Explained

D1: establish the team.

Form a skilled team first. Diversity matters here. Each member brings insights. Their combined expertise is crucial. Team formation kicks off the process.

D2: Describe the Problem

Articulate the issue clearly. Use quantifiable data here. Understanding the scope matters. Have accurate problem statements ready. They pave the way forward.

D3: Develop Interim Containment Action

Ensure a temporary fix. It limits the problem's impact. Speed is of the essence. However, ensure the action is effective. The goal is to stabilize the situation.

D4: Determine Root Cause

Dig deep into causes. Use data-driven analysis. Techniques include fishbone diagrams. Five Whys is also popular. Root cause analysis is pivotal. It prepares the team for corrective actions.

D5: Design and Verify Permanent Corrective Actions

Choose the best corrective action. Rigorous selection criteria apply. Effectiveness and efficiency matter. Verify through testing. Make certain the solution fits.

D6: Implement and Validate Permanent Corrective Actions

Roll out the solution. Watch closely for results. Validation takes place here. Use performance indicators for this. They must indicate that the solution works.

D7: Prevent Recurrence

Embed the improvement. Update systems and policies. Training may be necessary. Maintain the gains. This step safeguards the future. Documentation is important here.

D8: Congratulate the Team

Never overlook recognition. Acknowledge everyone's efforts. Celebrate the success achieved. It boosts team morale. It also promotes a culture of quality.

Interplay Between Steps

The interdependence is strong. Each step builds on the previous one. For example, a strong team in D1 enhances problem understanding in D2. Similarly, effective interim actions in D3 set the stage for a thorough root cause analysis in D4.

The verification in D5 ensures the solution from D4 is sound. Implementation in D6 then relies on the verified action. To prevent recurrence (D7), one must understand the root cause. The entire process relies on clear communication. Team recognition (D8) closes the loop neatly. It paves the way for future problem-solving success.

In essence, the 8D steps are interlinked. Each step informs the next. Teams achieve the best results by following the sequence. They also adapt as needed. 8D enforces a discipline that leads to high-quality results. The interaction between steps ensures problems do not just disappear. They stay solved. This is the power of an integrated problem-solving approach.

Can you provide some practical examples of the effective application of 8D Problem Solving strategies in real-life settings?

Understanding 8d problem solving.

8D problem solving stands for Eight Disciplines. It involves steps that teams must follow. Starting from identifying problems , it goes until preventing reoccurrences . Companies use 8D to tackle complex issues. Its main goal remains quality improvement.

Here are practical examples where 8D shines.

Example 1: Automotive Industry

D0: Plan - An auto manufacturer formed a team. Their goal was clear: resolve brake failures.

D1: Team Formation - They gathered experts from diverse fields. Collaboration was key here.

D2: Describe the Problem - They identified specific issues. Customers reported brakes failing at high speeds.

D3: Develop Interim Containment - They distributed quick-fix kits to dealerships. This ensured immediate customer safety.

D4: Determine Root Causes - A deep dive ensued. The team discovered a faulty brake fluid line.

D5: Choose and Verify Permanent Corrective Actions (PCAs) - They redesigned the brake line. Then they tested it under rigorous conditions.

D6: Implement and Validate PCAs - The new design went into production. Ongoing assessments confirmed its effectiveness.

D7: Take Preventive Measures - They updated their design guidelines. Thus, they eliminated the possibility of similar failures.

D8: Congratulate Your Team - Management recognized the team's effort. This promoted a culture of problem-solving.

Example 2: Electronics Manufacturer

D0: Plan - A sudden surge in returned gadgets prompted action.

D1: Team Formation - A cross-functional team took charge. They had one aim: find the flaw.

D2: Describe the Problem - Devices were overheating during usage. Anxiety among customers grew.

D3: Develop Interim Containment - They halted the production line. Assessing risks was necessary.

D4: Determine Root Causes - Detailed analysis revealed a substandard battery component.

D5: Choose and Verify PCAs - They sourced a higher quality component. Subsequent tests showed promising results.

D6: Implement and Validate PCAs - They integrated the new component into production. Monitoring phases ensured it was a fix.

D7: Take Preventive Measures - They revamped their quality control protocols. Now they could avoid similar issues.

D8: Congratulate Your Team - The team's innovative approach earned praise. They set new standards in their processes.

Example 3: Food Packaging Company

D0: Plan - Reports of packaging leaks triggered an 8D.

D1: Team Formation - Experts from production to distribution joined forces. They understood the stakes were high.

D2: Describe the Problem - The leaks were sporadic but damaging. Food safety concerns escalated.

D3: Develop Interim Containment - They removed compromised products from shelves. Protecting the consumer was paramount.

D4: Determine Root Causes - Investigation exposed a sealing machine defect.

D5: Choose and Verify PCAs - Engineers redesigned the sealing mechanism. Trials followed, proving success.

D6: Implement and Validate PCAs - The updated machines replaced the old ones. Continuous evaluations followed to assure quality.

D7: Take Preventive Measures - They introduced more rigorous maintenance routines. They aimed to preempt future failures.

D8: Congratulate Your Team - The swift and thorough response earned accolades. They reinforced trust in their brand.

8D's Practical Value

Each example showcases 8D's potential. This problem-solving framework adapts to various scenarios. Through structured teamwork and analysis, it guides toward sustainable solutions. It helps in ensuring the same problem does not occur twice. Businesses across different sectors find 8D crucial for their continuous improvement efforts. It underlines that a methodical approach to problem-solving can yield significant long-term benefits.

How is the effectiveness and success of the 8D Problem Solving approach measured in practical applications?

Introduction to 8d problem solving.

The 8D Problem Solving approach stands as a structured methodology. It aims to address and resolve critical issues within an organization. Rooted in the team-oriented approach, 8D follows eight disciplined steps. These steps ensure a comprehensive and effective resolution process. The process includes identifying the problem, implementing interim controls, defining root causes, developing a corrective action plan, taking corrective actions, validating those actions, preventing recurrence, and finally congratulating the team.

Measuring Effectiveness and Success

Quantitative metrics.

Timeliness of Response

The promptness of the initial response is critical. It alerts stakeholders to the emergence and acknowledgment of the issue.

Problem Recurrence Rates

A key success indicator is the frequency of problem recurrence. A declining trend signifies effective corrective actions.

Financial Impact

Cost savings or avoidance measures the fiscal efficiency of the resolution. It counts both direct and indirect factors.

Cycle Time Reduction

Improvements in processes can lead to shorter cycle times. This reflects efficiency gains from the 8D implementation.

Qualitative Metrics

Quality of Documentation

Comprehensive documentation ensures thorough issue analysis. It captures the nuances of the problem-solving journey.

Stakeholder Satisfaction

Feedback from affected parties gauges the outcome’s acceptability. Satisfaction levels can direct future interventions.

Knowledge Transfer

Disseminating learnings enhances organizational capability. Sharing insights leads to broader, preventive measures.

Team Cohesion and Growth

Personal and team development signal process benefits. Such growth provides intangible value to the organization.

Practical Application and Continuous Improvement

In practical applications, tailoring metrics to contexts is vital. Unique business environments demand specific success criteria. Therefore, adapting the approach and its measurement system is necessary.

Organizations may employ a combination of tangible and intangible metrics. Aligning these to strategic goals ensures relevance. The 8D Process receives fine-tuning through iterative cycles. Each cycle offers an opportunity for enhanced problem-solving efficacy.

The Importance of Measure Standardization

Standardizing the measurement process ensures consistency. It aids in comparing and benchmarking against best practices. Homogeneity in measures facilitates clearer communication. It enhances the understanding of successes and areas for improvement.

Revisiting and Refining the 8D Process

Upon completion, a rigorous review of the 8D process is crucial. It ensures learnings lead to process refinement. Alterations in measures might follow to better reflect evolving business needs. This ongoing evolution drives the sustained value of the 8D methodology.

The 8D Problem Solving approach, with its disciplined steps, delivers a robust framework. Measuring its effectiveness requires a blend of quantitative and qualitative metrics. These metrics, when standardized and continually refined, offer a clear lens to assess the 8D process's success. They help organizations not just to solve problems but to evolve in their problem-solving capabilities.

He is a content producer who specializes in blog content. He has a master's degree in business administration and he lives in the Netherlands.

Decision Tree: A Strategic Approach for Effective Decision Making

Lateral Thinking for Problem-Solving: Find the Haystack!

Unlocking Problem Solving Skills: Where Do Problems Come From?

Developing Problem Solving Skills Since 1960s WSEIAC Report

Advisory boards aren’t only for executives. Join the LogRocket Content Advisory Board today →

- Product Management

- Solve User-Reported Issues

- Find Issues Faster

- Optimize Conversion and Adoption

An overview of the 8D problem-solving method

The 8D problem-solving method is a powerful tool in product management. It’s designed to help product managers tackle issues systematically and enhance product quality. This method follows eight steps in total, hence the name 8D.

The steps range from identifying problems to implementing long-term solutions. Today you’ll explore how you can effectively apply 8D to your products. You’ll also learn about the benefits of using this approach and analyze some real case studies.

What is 8D?

The 8D problem-solving method is designed to address and resolve problems by identifying, correcting, and eliminating recurring issues.

It involves eight different steps:

- Plan — Prepare for the problem-solving process

- Team selection — Assemble a team with the necessary knowledge and skills

- Problem definition — Clearly define the problem and its impact

- Interim containment action — Implement temporary measures to contain the problem

- Root cause identification — Identify the underlying cause(s) of the problem

- Permanent corrective action — Develop and implement a solution to address the root cause

- Preventive measures — Take steps to prevent the recurrence of the problem

- Team recognition — Acknowledge and reward the team’s efforts in resolving the issue

These steps focus on root cause analysis, preventive measures, and long-term solution implementation. The end goal is to improve product quality and operational efficiency.

The eight disciplines of 8D

The eight disciplines of the 8D method represent a comprehensive approach to solve problems within an organization. Each discipline is designed to guide teams through the process at each stage. Here’s a deeper look into each stage:

This initial step involves preparing for the problem-solving process. The goal here is to understand the problem’s magnitude and set up objectives. It’s about getting ready to tackle the issue systematically.

Team selection

In this step, a cross-functional team is formed. The team should consist of individuals with the necessary knowledge, skills, and experience to address the problem effectively. The team works together throughout the 8D process.

Problem definition

Next, the team has to describe the issue in specific terms. The goal here is to understand the impact and scope of the complication. A well-defined problem is easier to solve.

Interim containment

In the process of finding a solution, temporary measures are taken to contain the problem and prevent it from worsening. This reduces further damage or impact to the involved operations.

Root cause identification

In this phase, the team uses various tools and techniques to identify the underlying cause of the problem. An understanding of the root cause is essential for developing an effective, lasting solution.

Permanent corrective action

With the root cause identified, the team moves to develop a permanent corrective action plan to resolve the issue. Now, the team needs to choose the best solution, implement it, and monitor its effectiveness. This analysis will ensure that the problem is truly resolved.

Over 200k developers and product managers use LogRocket to create better digital experiences

Preventive measures

With such vast processes, there is always a possibility of the problem recurring. To resolve this, the team identifies and implements measures that address the root cause. There might be a need for changes to different aspects of the overall approach.

Team recognition

The final stage focuses on acknowledging and rewarding the team’s efforts. Recognizing the team’s hard work and success in resolving the issue is important for morale. It also promotes a culture of continuous improvement.

By following these eight disciplines, product managers can solve problems more effectively. The other benefit is that it builds a proactive culture that addresses issues before they escalate.

Applying 8D in product management

Applying the 8D problem-solving method in product management involves leveraging its structured approach. This helps you eliminate problems and process improvement initiatives.

Problem identification

The 8D process begins with gathering data and feedback to quickly identify potential issues. After that, a diverse team from various departments works together to uncover issues. And finally, the team solves the problems efficiently.

Once a problem is spotted, quick fixes are applied to limit its impact. Simultaneously, you explore root causes of an issue using methods like the Five Whys . The final step is to implement the solution based on these insights. Occasionally, redesigns or process upgrades are also used to resolve the issue thoroughly.

Elimination

To eliminate recurring problems, it’s crucial to establish preventive measures. Several steps support the main goal of elimination including process adjustments, quality control improvements, and updates to design standards.

The insights gathered from each 8D cycle help with continuous improvement. It also aids in formulating strategies to avert future issues.

Benefits of the 8D method

The main benefit of using the 8D method is its impact on teamwork and continuous improvement. The more obvious benefits focus on root cause analysis and prevention of issues:

- Enhanced quality control

- Efficient problem resolution

- Systematic and thorough approach

- Teamwork and knowledge sharing

- Focus on root cause analysis

- Reduced recurrence of issues

- Cost reduction

- Improved customer satisfaction

The systematic approach to address issues ensures that no effort goes to waste. Eventually, it helps the teams to quickly propose long-term solutions to a range of problem patterns.

Challenges in implementing 8D

The 8D problem-solving method is extremely valuable when used in the right manner. However, there can be challenges at every stage of this process. Because of this, it’s beneficial for you to have an understanding of how to quickly identify these challenges.

These include:

- Resistance to change among team members

- Insufficient teamwork and collaboration

- Lack of training on the 8D methodology

- Difficulties in data collection and analysis

How to solve them?

- Clearly communicate benefits to overcome resistance

- Foster collaboration and teamwork among participants

- Provide targeted training on the 8D process

- Encourage data analysis for effective problem-solving

For a deeper understanding, let’s take a look at two case studies of how the 8D process can enhance the product management workflow.

Real-life examples of 8D

A leading tech company, (similar to Apple) faced public backlash over smartphones overheating and reduced battery life. In this context, the 8D method helped to quickly identify and contain the issues.

The root cause analysis helped it track the problem back to a battery design flaw. Collaborative efforts with the battery supplier led to a redesigned battery and an update to the operating system. This not only resolved the issue but also restored consumer trust. Eventually, the brand’s reputation for quality was restored.

Similarly, a major automaker found a software glitch in its driver-assistance systems. This issue was risking driver safety. Using the 8D method, it pinpointed outdated algorithms as the root cause. The solution was simple, it issued a software update and enhanced its development processes.

Both of these examples are evidence of how the 8D method can be utilized to prevent complications efficiently.

Key takeaways

In wrapping up, it’s clear that this approach is more than just a procedure. Think of it as a strategic framework designed for the product manager. The 8D method equips you with a robust toolkit for addressing and preempting issues, systematically.

On top of that it helps you to:

- Promote teamwork and continuous improvement

- Reduce problem recurrence through root cause analysis

- Overcome implementation challenges with effective communication

Feel free to comment with any questions you may have!

Featured image source: IconScout

LogRocket generates product insights that lead to meaningful action

Get your teams on the same page — try LogRocket today.

Share this:

- Click to share on Twitter (Opens in new window)

- Click to share on Reddit (Opens in new window)

- Click to share on LinkedIn (Opens in new window)

- Click to share on Facebook (Opens in new window)

- #agile and scrum

- #project management

Stop guessing about your digital experience with LogRocket

Recent posts:.

Leader Spotlight: The importance of being a good storyteller, with David Bloom

David Bloom shares the importance of storytelling in product, and how talking to people the right way enables them to be effective.

How to use concept map templates for brainstorming

Joseph D. Novak introduced concept mapping during the 1970s to visualize the evolving scientific understanding of students.

Leader Spotlight: Enabling and leveraging live video commerce, with Andrew Chen

Andrew Chen, Chief Product Officer at CommentSold, discusses how live video is transforming ecommerce opportunities for brands.

A guide to success metrics

Success metrics are measurable parameters used to measure progress, effectiveness, and ultimately, success.

Leave a Reply Cancel reply

8D Chess: How to Use The 8 Disciplines for Problem Solving

Hospitals have developed something of a reputation for being rife with bad processes . When processes aren’t adequate, the result is an abundance of “workarounds”.

For example, when equipment or supplies are missing, a nurse might waste time running around searching for what is needed, and once the item is found, return to their previous duties.

One study indicates that nurses spend 33 minutes of a 7.5-hour shift completing workarounds that are not part of their job description.

This may well “put out the fire” so-to-speak, but really it is just a hastily applied band-aid that does nothing to treat the root cause of the problem.

More time is wasted and more problems will arise in the future because nothing has been done to prevent the initial problem from happening again.

Individual nurses are not at fault here; workplace culture often values expertise in the form of those who “get the job done”, which tends to pull against the notion of spending time building good processes (time in which the job is perhaps not “getting done”).

So how to approach the problem of problem solving ?

In a lean context, problem solving can be distilled into two simple questions:

- What is the problem and how did it happen?

- How can we make sure that it doesn’t happen again?

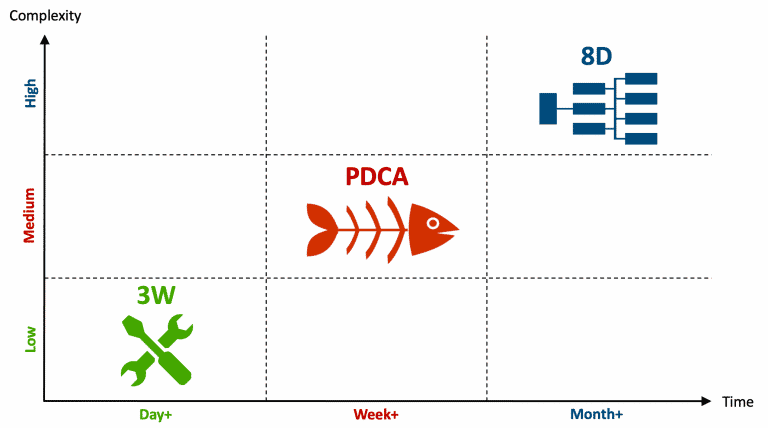

The 8D, or eight disciplines methodology, is a problem solving process – most likely one of the most widely used problem solving processes out there. It is used by many different countries, in many different industries, and many different organizations.

8D is designed to help you put out those fires, and make sure they don’t happen again.

In this article, I’ll introduce you to the 8D problem solving methodology and provide you with an outline of the basic process that you can hopefully apply in your own business, plus how you can enhance 8D with other tools and methodologies like Six Sigma , FMEA , and Process Street .

Here’s what I hope you’ll take away after reading:

- An understanding of the basics of 8D

- Advantages of using 8D

- The purpose and objectives of each phase of the 8D process

- An understanding of how to use 8D for problem solving

- How 8D works with other problem solving tools

- How you can use Process Street to maximize the potential of the 8D framework

Let’s begin with the origins of 8D – what is it, and where did it come from?

What is 8D?

8D (sometimes Global 8D or G8D) stands for eight disciplines, and is a problem solving methodology. It’s basically a process for understanding and preventing problems.

Much like how risk management seeks to take a proactive, preventative stance, 8D aims to gain insight into the root causes of why the problems happen, so they won’t happen again.

The 8D process involves eight (sometimes nine) steps to solve difficult, recurring problems. It’s a transparent, team-based approach that will help you solve more problems in your business.

8D origins: Where did it come from?

Despite the popular story that 8D originated at Ford, it was in fact developed in 1974 by the US Department of Defence, ultimately taking the form of the military standard 1520 Corrective Action and Disposition System for Nonconforming Material .

Ford took this military standard, which was essentially a process for quality management , and expanded on it to include more robust problem solving methods.

In 1987, Ford Motor Company published their manual, Team Oriented Problem Solving (TOPS) , which included their first iteration of the 8D methodology.

Initially termed Global 8D (or G8D) standard, it is currently used by Ford and many other companies in the automotive supply chain.

8D, PDSA, & other problem solving processes

The disciplines of 8D follow the same logic as the Deming Cycle (also known as PDSA, and sometimes PDCA).

PDSA stands for Plan, Do, Study, Act (or Check, in the case of PDCA).

The similarity lies in the fact that both PDSA and 8D are designed to be used to improve processes. They’re both examples of cycles of continuous improvement.

Whereas 8D may be painted as a more generic problem-solving framework, structurally speaking both 8D and PDSA share a lot in common.

The simple idea of beginning with a clear objective, or desired output, and then testing, analyzing , and iteratively tweaking in a continuous cycle is the basis for both methodologies.

There are, of course, differences. We’ll cover the different applications of both 8D and PDSA in this article.

8D advantages

One of the main strengths of 8D is its focus on teamwork. 8D philosophy encourages the idea that teams, as a whole, are more powerful than the sum of the individual qualities of each team member.

It’s also an empirical methodology; that is to say that it is a fact-based problem solving process.

A branch of continuous improvement, proper use of 8D will help you coordinate your entire team for effective problem solving and improved implementation of just about all of the processes used in your business.

The 8 disciplines for problem solving

As you may have noticed, we’re starting with zero, which makes nine total disciplines. This “zero” stage was developed as an initial planning step.

D0: Plan adequately

Make comprehensive plans for solving the problem including any prerequisites you might determine.

Be sure to include emergency response actions.

D1: Establish your team

Establish your core team with relevant product or process knowledge. This team will provide you with the perspective and ideas needed for the problem solving process.

The team should consist of about five people, from various cross-functional departments. All individuals should have relevant process knowledge.

A varied group will offer you a variety of different perspectives from which to observe the problem.

It is advisable to establish team structure, roles, and objectives as far ahead in advance as possible so that corrective action can begin as quickly and effectively as possible.

D2: Describe the problem

Have your team gather information and data related to the problem or symptom. Using clear, quantifiable terms, unpack the problem by asking:

D3: Contain the problem (temporary damage control)

Depending on the circumstances, you may need to mobilize some kind of temporary fix, or “firefighting”.

The focus of this stage should be on preventing the problem from getting worse, until a more permanent solution can be identified and implemented.

D4: Identify, describe, and verify root causes

In preparation for permanent corrective action, you must identify, describe, and verify all possible causes that could contribute to the problem happening.

You can use various techniques for this, including a Failure Modes and Effects Analysis , or Ishikawa (fishbone) diagram .

It’s important that the root causes are systematically identified, described in detail, and promptly verified (or proved). How each cause is verified will depend on the data type and the nature of the problem.

Take a look at the section towards the end of this article for some more problem solving tools to help you decide the right approach.

D5: Identify corrective actions

You must verify that the corrective action you identified will in fact solve the problem and prevent it from happening again in the future (or whatever is your desired threshold of recurrence).

The best way to do this is to collect as much data as possible and by performing smaller-scale “pilot” tests to get an idea of the corrective action’s impact.

You can’t begin to identify the optimal corrective action until you have identified the root cause(s) of the problem.

D6: Implement and validate corrective actions

Carry out the corrective actions, and monitor short and long term effects. During this stage, you should assess and validate the corrective actions with empirical evidence.

Discuss and review results with your team.

D7: Take preventative measures (to avoid the problem happening again)

Here is where you make any necessary changes to your processes, standard operating procedures , policies , and anything else to make sure the problem does not happen again.

It may not be possible to completely eliminate any chance of the problem recurring; in that case, efforts should focus on minimizing possibility of recurrence as much as possible.

D8: Congratulate your team

It’s important to recognize the joint contribution of each and every one of the individuals that were involved in the process.

Team members should feel valued and rewarded for their efforts; this is crucial and perhaps the most important step – after all, without the team, the problem would not have been fixed.

Providing positive feedback and expressing appreciation helps to keep motivation high, which in turn improves the sense of process ownership and simply increases the likelihood your team will actually want to improve internal processes in the future.

How to use 8D for problem solving

The 8D method above outlines a proven strategy for identifying and dealing with problems. It’s an effective problem solving and problem prevention process.

In addition to avoiding long-term damage from recurring problems, 8D also helps to mitigate customer impact as much as possible.

More than just a problem-solving methodology, 8D sits alongside Six Sigma and other lean frameworks and can easily be integrated with them to minimize training and maximize efficacy.

8D is definitely a powerful framework on its own, but it really shines when combined with other synergistic concepts of lean and continuous improvement.

More problem solving tools that synergize well with 8D

8D has become a leading framework for process improvement, and in many ways it is more prescriptive and robust than other more simplistic Six Sigma approaches.

However, there are many Six Sigma methodologies, and even more frameworks for problem solving and process improvement .

The following improvement tools are often used within or alongside the 8D methodology.

DMAIC: Lean Six Sigma

DMAIC stands for: