- +1 (800) 826-0777

- VIRTUAL TOUR

- Mass Notification

- Threat Intelligence

- Employee Safety Monitoring

- Travel Risk Management

- Emergency Preparedness

- Remote Workforce

- Location and Asset Protection

- Business Continuity

- Why AlertMedia

- Who We Serve

- Customer Spotlights

- Resource Library

- Downloads & Guides

Safety Moment Ideas: 24 Topics for a Strong Discussion

Prepare your company and your people for whatever risks they might face with these 24 ideas for “safety moment” meetings.

What Is a Safety Moment?

- How and When to Integrate Safety Talks

- 24 Safety Moment Ideas for 2024

Training is one of the key elements of effective safety leadership . You need to establish a pattern of consistent communication, educating your company’s employees on the risks they face in the workplace and the best strategies to protect themselves.

Sometimes, this is easier said than done. Even the most engaged employees struggle to give safety meetings and training sessions their full attention. Research has found that most presentations lose audience attention within the first 10 minutes. A safety meeting agenda can aid in structuring effective and engaging meetings.

You need a way to integrate education into your organization’s daily activities without risking information overload. Enter the safety moment. Concise, direct, and easily digested, it’s an ideal way to share and reinforce critical safety information.

In this article, we’ll outline what safety moments are, how you can maximize them, and a variety of safety moment ideas to help keep your people safe.

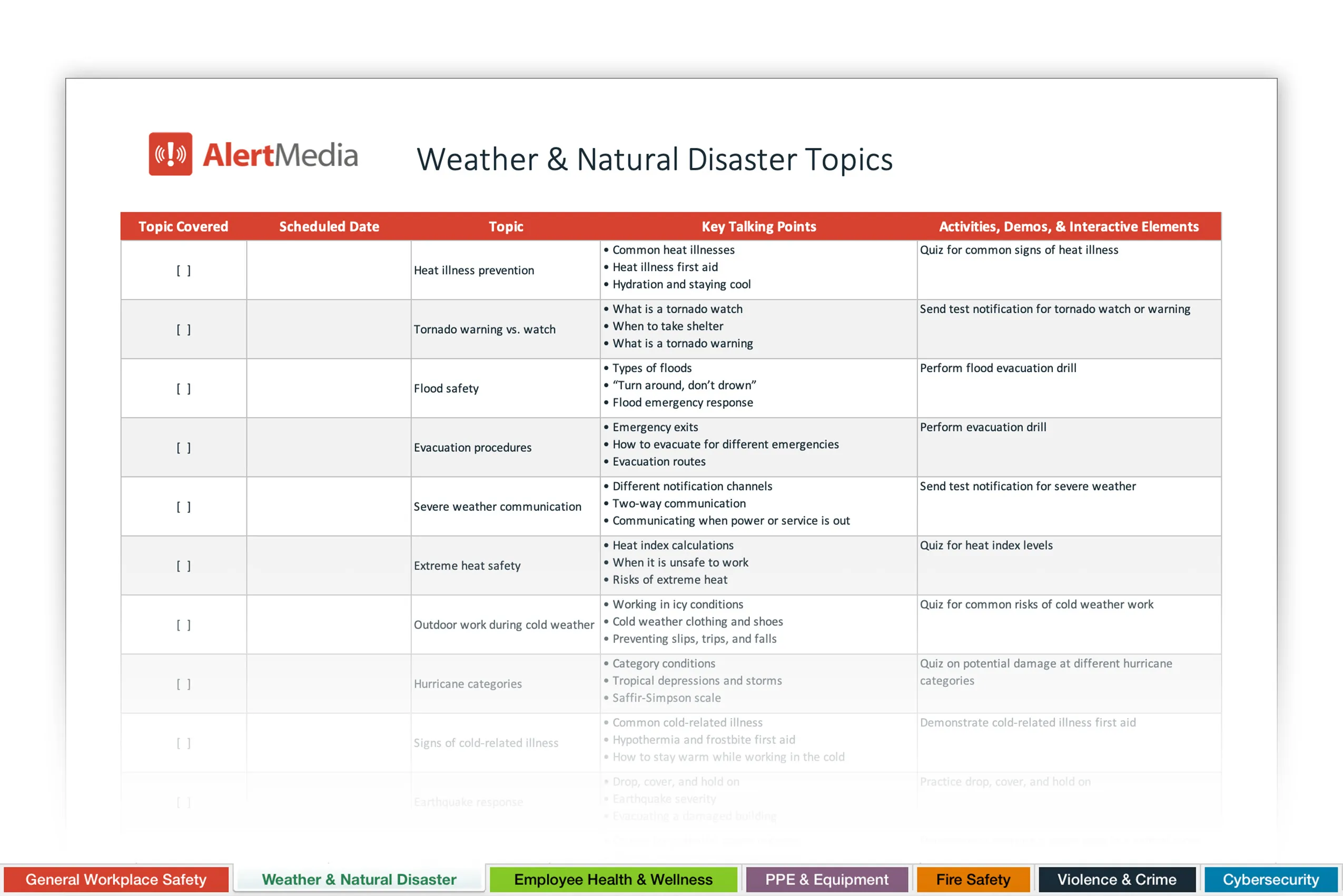

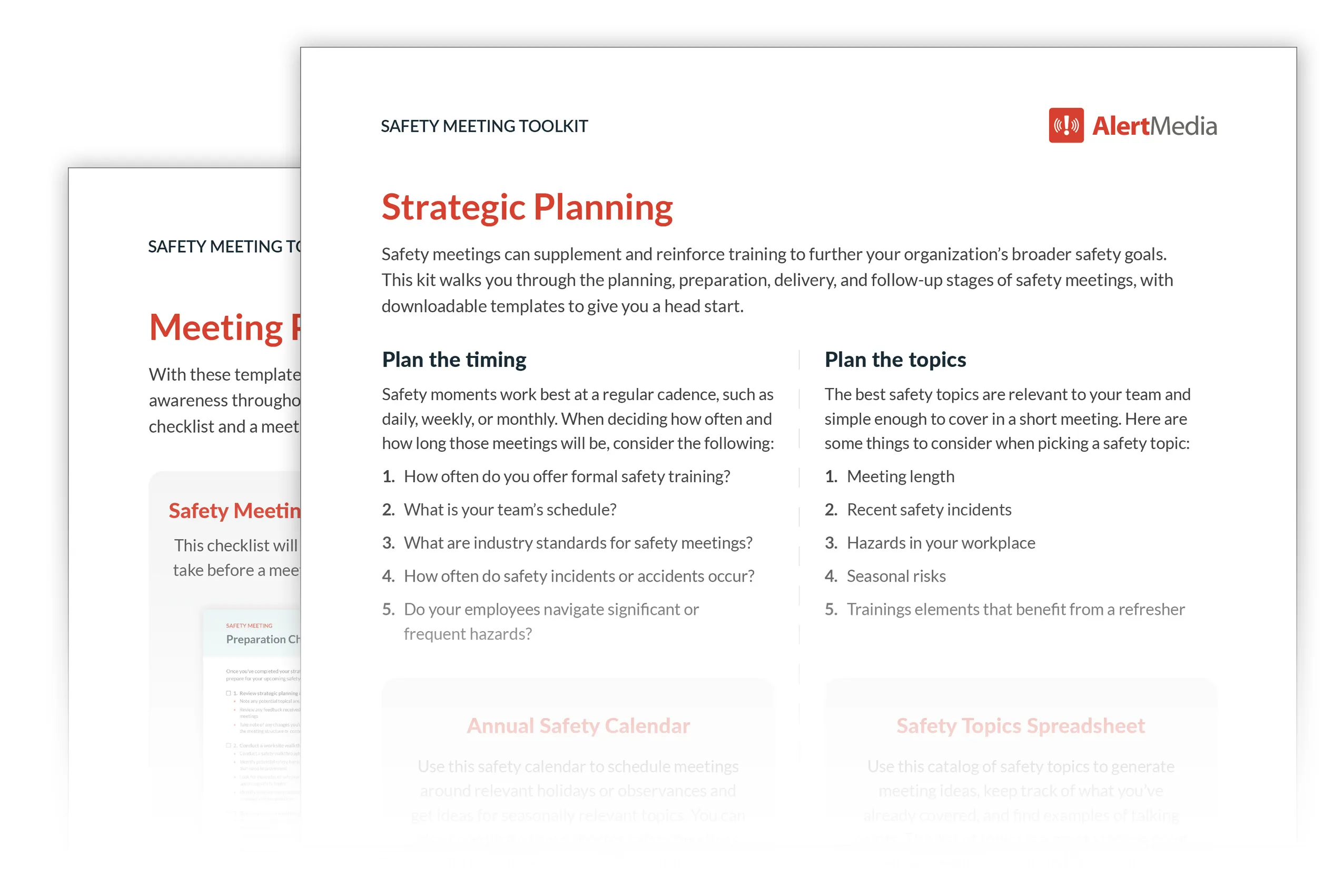

Preview of a spreadsheet full of safety meeting topics with talking points

Safety Meeting Toolkit

A safety moment is a brief talk about a specific, safety-oriented topic at the beginning of a meeting. A safety moment is usually between 5–10 minutes long and may also be called “safety minutes,” “safety chats,” or “safety shares.”

Teams can approach these conversations in different ways to maximize the impact. But there are a few common aspects to most companies’ safety moments:

- Keep them short, usually lasting approximately five minutes and never more than 10

- Focus on a single topic rather than jumping around or overloading participants with information

- Orient the safety moment toward your team’s upcoming day or week, not long-term planning

- Use safety moments to support a positive safety culture through clear, concise, and engaging communication

Safety moments vs. toolbox talks

You might have heard the term “toolbox talks” and wonder how they compare to safety moments. The tradition of toolbox talks may have begun on construction sites or similar worksites where there is a need to regularly brush up on equipment safety procedures. This term is used in diverse workplaces today, just as safety moments are used to establish regular informal discussions of actionable safety information.

In any case, the meaning of each of these terms is rooted in how teams use them—rather than strict definitions—and there is bound to be a wide variety of approaches to supporting safety outcomes for unique industries, organizations, and leadership teams.

Along with “safety moments” and “toolbox talks,” other common names include “safety minutes,” “ safety talks ,” and “tailgate meetings.” To choose an effective name, consider the tone and goals you’re aiming for—and the setting for your talks. What resonates for a roofing company may not resonate for an accounting firm.

Watch this video to learn the fundamentals of compelling safety talks, discover new topic ideas, and get facilitation tips.

Why are safety moments important?

Safety moments are a valuable tool to deliver or reinforce critical information. Topics can cover routine issues but are also a great way to highlight timely hazards. Say, for example, your team is operating heavy machinery they haven’t worked with in a few months. At the start of the day, a quick safety moment covering the risks and precautions can help ensure everyone is aware and prepared.

Safety shares are also a great way to encourage safety engagement . Routine safety training can sometimes feel abstract and easy to tune out. But since safety moments cover topics that are immediately relevant, employees are more likely to give their full attention and participation to the safety message of the day.

How and When to Integrate Safety Moments

The ideal frequency and format for safety moments vary by setting and industry. Companies with workers based mostly in offices will usually hold safety moments in conference or break rooms. And given the less hazardous environment, weekly safety moments may be sufficient. They can also be a great complement to your monthly safety topics .

Conversely, higher-risk workplaces like warehouses or construction sites might hold daily moments to reinforce salient points and help prepare workers for what they’re doing that day.

24 Safety Moment Ideas for 2024 and Beyond

To determine the most productive safety meeting topics for your workplace, first perform a business threat assessment . No two organizations—or even worksites within an organization—face the same risks. Offices, kitchens, factories, and construction sites all have unique conditions that can impact your employees’ workplace safety . When you have a clear understanding of the hazards that might impact your people, you can plan for training sessions, including safety moments to address smaller safety topics or refreshers of more in-depth training.

Here are 24 safety moment ideas to improve general safety and inspire detailed presentations about the hazards in their work environments.

Universal safety moment topics

1. situational awareness.

One of the most important skills you can help your employees develop is situational awareness in the workplace . Spend a few minutes to emphasize the value of staying focused on the task at hand and being cognizant of your surroundings to reinforce your broader situational awareness training programs. You can give actionable tips for minimizing distractions or reviewing a short safety checklist before putting full attention on a potentially hazardous task.

2. Emergency exits and routes

Every workplace must have clearly marked emergency exits. While safety moments can’t replace fire drills , they serve as a good reminder of where the nearest exit is and how to safely reach it. This brief check-in would also be a good time to make sure people are aware of where evacuation routes are posted for easy reference in various locations throughout the workplace.

3. Security and access control

Whether it’s accidental or intentional, someone’s presence where they shouldn’t be creates a workplace risk. Cover the security policies for the group you’re talking to, as well as protocols for reporting a breach.

4. Fire prevention and preparedness

Workplace fire prevention is a broad topic that you can break down into several fire safety moments. For example, you can discuss how to avoid fire hazards , where fire extinguishers are and how to use them, what each employee’s role is in case of a fire, and where to meet after evacuating.

5. The importance of proper rest

What happens at home can indirectly influence workplace hazards. Employees who don’t get enough rest can fatigue more easily and make mistakes, putting themselves and their coworkers at risk of injury. You can encourage sufficient rest for health and safety reasons and review workday break schedules to ensure people are taking advantage of chances to rest and recharge while on the job.

6. Parking lot safety

At the end of a workday, it can be tempting to stare at your phone, catching up on messages while you walk to the car. However, between trucks with poor visibility, distracted drivers, and potential threats lurking in dark corners, parking lots are full of hazards to be aware of. Review any risks particular to your parking areas and tips for staying aware, avoiding known hazards, and how to contact reliable assistance if needed.

7. Two-way communication with safety leaders

A two-way communication platform that includes mass notification and employee check-in functionality is key to any safety program. But it’s effective only if your team uses it properly. Review how and when employees should expect to receive notifications, as well as how to check in and report threats.

Industrial, warehouse, and construction safety moment topics

8. personal protective equipment usage.

Personal protective equipment (PPE) is part of many workers’ routines, but it’s often taken for granted. Periodic reminders about issues like properly fitting hard hats, hearing protection, and testing air filters and respirators could prevent serious injury.

9. Heat stress prevention

As OSHA prepares to release its first-ever set of heat regulations , it’s a good time to remind employees about the risks of heat exposure and heat exhaustion. Focus on prevention , early warning signs, and how workers can help keep each other safe in hot situations .

10. Forklift safety

Forklifts can be as dangerous for operators as they are for anyone in the vicinity. Discuss the rules for properly operating a forklift, such as speed and load limits, as well as the use of visual and audio cues to keep routes clear. A popular solution is to lay down brightly colored tape to designate driving lanes and no-go zones to keep pedestrians safe.

11. Heavy machinery

When someone spends long enough working with heavy machinery, the inherent danger can begin to feel routine. While experience is valuable, complacency is dangerous. Use safety briefings to remind workers of the risks and safety procedures to follow for each piece of equipment every time.

12. Hazardous materials and chemicals

Chemicals and other hazardous materials always present a risk, no matter how often your team may work with them. Review the specific risks and warnings of materials present in the workplace, and teach how to properly respond in the event of a spill or exposure.

13. Injury treatment and reporting

No matter how much effort you put into prevention, accidents happen. In the event of an injury, workers need to know where to seek out first aid, when to go straight to the hospital, and how to comply with OSHA incident reporting regulations .

Retail and hospitality safety moment topics

14. avoiding slips, trips, and falls.

Workplace injuries caused by slips, trips, and falls cause workers to miss an average of 14 days of work . Go over common hazards to watch for in your work environment, as well as the process for reporting and mitigating the risks.

15. Piling, stocking, and shelving hazards

Crowded aisles, tall stacks and full shelves can create potential hazards for employees and customers. Review how to properly store, stack, and display inventory, as well as good habits for avoiding cluttered emergency exit routes.

16. Safe lifting techniques

Standing for long periods of time can lead to back and leg injuries, especially when combined with bending over to lift objects. Provide frequent safety tips on good posture, the importance of appropriate footwear, and how to properly lift items to avoid injury.

17. Shoplifting and robbery protocols

If an employee faces theft or an armed robber, they need to know exactly how to handle the situation. A quick safety toolbox talk can refresh employees on what to do, how to protect themselves, and who to contact once everyone is safe.

18. Knife safety

There’s a common saying that a falling knife has no handle. Anyone who works in a kitchen has heard this a thousand times, but talking about how to properly handle and care for knives can help prevent an unfortunate injury.

19. Working with heat and flames

Hot surfaces and open flames from stoves, ovens, broilers, and deep fryers can all cause serious injuries. Quick safety talks focusing on each of these hazards can keep your kitchen staff aware of the risks and focused on doing their jobs safely.

Office environment safety moment topics

20. cybersecurity.

Researchers estimate that cyberattacks happen an average of every 39 seconds . Reviewing how to avoid phishing scams, social engineering, and unsafe attachments could save your company from a costly and painful data breach or malware infection.

21. Electrical safety

Offices might seem safe compared to industrial settings, but anything that plugs in can be a hazard. Frayed cords, overloaded surge protectors, and malfunctioning kitchen equipment can all lead to fires, and your team should know how to identify and address these risks before a crisis develops.

22. Proper ergonomics

When you spend most of the day in front of a desk, you need a setup that’s easy on your body. Avoid repetitive stress injuries by discussing the details of proper ergonomics, including chair height and posture, desk height, monitor angle and orientation, and how to position keyboards and mice.

23. Eye strain

The more time someone spends staring at screens, the higher the risk of eye injuries. Going over ways to mitigate eye strain, such as screen filters and appropriate lighting, can help employees stay productive without impacting their vision.

24. The importance of regular breaks

Since sitting at a desk all day isn’t physically demanding, people might not think they need to take breaks. However, prolonged sitting can cause physical injuries, contribute to eye strain, and lead to mental fatigue. Remind employees not only to pause their work periodically but also to stand up and walk around for 5 to 10 minutes every hour.

Putting Safety Moments to Work

A consistent feedback loop of training, education, and practice is an essential component of a strong safety culture . Safety moments are a great way to complement more extensive and rigorous training programs, as they allow you to reinforce concepts on a more frequent basis.

In industrial settings, safety moments can set the tone for the day. Whether you’re reviewing a common topic or describing a new risk, an engaging discussion can get workers focused on keeping themselves and their peers safe. Five minutes every morning to ensure everyone goes home healthy and happy is time well spent.

More Articles You May Be Interested In

Please complete the form below to receive this resource.

Check Your Inbox!

The document you requested has been sent to your provided email address.

Cookies are required to play this video.

Click the blue shield icon on the bottom left of your screen to edit your cookie preferences.

- All Resource

PPT Templates

Single slides.

- Pitch Deck 207 templates

- Animation 326 templates

- Vertical Report 316 templates

- Business 799 templates

- Finance 56 templates

- Construction 45 templates

- IT/Commerce 171 templates

- Medical 64 templates

- Education 45 templates

- Lifestyle 390 templates

- Pitch Decks 138 templates

- Business 539 templates

- Finance 20 templates

- Construction 75 templates

- IT/Commerce 73 templates

- Medical 27 templates

- Lifestyle 578 templates

- Pitch Decks 140 templates

- Business 469 templates

- Finance 19 templates

- Construction 64 templates

- IT/Commerce 72 templates

- Medical 29 templates

- Education 39 templates

- Lifestyle 490 templates

- Cover 266 templates

- Agenda 97 templates

- Overview 216 templates

- CEO 28 templates

- Our Team 142 templates

- Organization 48 templates

- History 38 templates

- Vision, Mission 109 templates

- Problem, Solution 193 templates

- Opportunity 154 templates

- Business Model 158 templates

- Product, Services 299 templates

- Technology 65 templates

- Market 155 templates

- Prices 56 templates

- Customers 55 templates

- Competitor 113 templates

- Business Process 151 templates

- Analysis 222 templates

- Strategy 120 templates

- Marketing, Sales 61 templates

- Profit, Loss 69 templates

- Financials 247 templates

- Timeline 122 templates

- Proposal 40 templates

- Contact Us 272 templates

- Break Slides 16 templates

- List 359 templates

- Process 351 templates

- Cycle 177 templates

- Hierarchy 98 templates

- Relationship 152 templates

- Matrix 86 templates

- Pyramid 67 templates

- Tables 145 templates

- Map 96 templates

- Puzzles 163 templates

- Graph 217 templates

- Infographics 436 templates

- SWOT 111 templates

- Icon 418 templates

- Theme Slides 138 templates

- Mockup 42 templates

- Column 315 templates

- Line 199 templates

- Pie 139 templates

- Bar 179 templates

- Area 130 templates

- X Y,Scatter 16 templates

- Stock 59 templates

- Surface 3 templates

- Doughnut 256 templates

- Bubble 65 templates

- Radar 83 templates

- Free PPT Templates 2,101 templates

- Free Keynote 2,017 templates

- Free Google Slides 2,098 templates

- Free Theme Slides 35 templates

- Free Diagram 126 templates

- Free Chart 49 templates

- New Updates

Result for ' industrial safety '

206 Templates are available.

- Sort by Accuracy

- Sort by Newest

industrial Business Pitch Deck Presentation PowerPoint

Presentation photos are included; Smart and innovative presentation slides Possible to change shape and color properties Rich, clean & modern slide High quality, editable pre-designed slides

Financial & industrial Plan Best PowerPoint Presentation

Modern, simple, and clean design 100% fully editable PowerPoint slides Easy editable data driven charts (pie, bar, line) Free images and artwork Easy color change

industrial Facility Best PPT Templates

Data charts (editable via Excel) 100% vector objects & icons Free images and artwork No animation template 16:9 aspect ratio Smart and innovative presentation slides

safety Public Work - Free Powerpoint Sample

Drag & drop image placeholders Non-animated Landscape orientation style Clean, modern, and creative slides

industrial City - Free Powerpoint Template

Modern and clean design All images included 4:3 aspect ratios Clean style

industrial Complex - Free PPT Sample

Easy to edit in PowerPoint Format: PowerPoint (.pptx) - designed with Microsoft PowerPoint 2016 Latest Templates support version Easy color change

industrial City - PowerPoint Free

Free images and artwork Non-animated Creative and innovative presentation slides Easy color change

Free Design Template - industrial Business

Smart and innovative presentation slides Free images and artwork Non-animated Easy color change

industrial & Factory Theme Templates

Scalable vectorial PowerPoint shapes and PowerPoint icons Shapes and text are 100% editable Possible to change shape and color properties Suitable for each industries Changable into PDF, JPG, and PNG formats

Factory industrial annual report ppt template

Scalable vectorial PowerPoint shapes and PowerPoint icons Shapes and text are 100% editable Created with high quality slides Suitable for each industries Professional look presentation

safety Business plan PPT Templates

Modern, simple, and clean design Built-in custom color palette Completely editable presentation template Color, size, shading etc. can be modified Modern layouts based on master slides

industrial Facility Simple PowerPoint Template Design

100% fully editable PowerPoint slides Easy to customize without graphic design skills Free font used Suitable for each industries Drag & drop friendly

Jigsaw Puzzle industrial Infographic Diagram

Easy to edit in PowerPoint Quick and easy to customize Easy to change colors Dark & light backgrounds 16:9, 4:3 aspect ratios

Trade Logistics Powerpoint Presentation

Quick and easy to customize Easy to change colors No animation template Modern and clean design Master layout with text placeholders

The Distribution Industry PowerPoint Presentation Slides

Easy to edit and customize Easy to change colors Format: PowerPoint (.pptx) - designed with Microsoft PowerPoint 2016 Non-animated All elements are editable Drag & drop image placeholders

Milling Machines Outline PPT Presentation

Highly editable presentation template. Easy to change colors Data charts (editable via Excel) 16:9 aspect ratio Professional business presentation

Global Indutry PPT Design

Possible to change shape and color properties Professionally designed Landscape orientation style Suitable for each industries High quality, editable pre-designed slides

About Steel Industry Business Strategy PPT

100% fully editable PowerPoint slides Easy editable data driven charts (pie, bar, line) Replaceable the image into placeholder Suitable for each industries Readily available in both 4:3 and 16:9 aspect ratio Modern layouts based on master slides

Construction Design PowerPoint Backgrounds

Easy customization Highly editable presentation template. Premium & modern multipurpose Created by professionals Suitable for creative projects Creatively crafted slides

Biometric Authentication PowerPoint Templates for Presentation

Replaceable the image into placeholder Created by professionals Created with high quality slides Premade color variation Suitable for each industries

1 / 11 page

Free Slides

Slide Members

All Rights Reserved 2024 © Copyright Slide Members

Information

- Privacy Policy

- Terms & Conditions

Recent Slides

- 19+ Recently Powerpoint Templates & Google slides Update

- 9+ New Powerpoint Templates & Google Slides Update

- 18+ New Templates Update (PPT templates & Google slides)

Analyse A Meter

What is Industrial Safety? Importance, Objectives and planning

The thousand of industrial accidents every year caused the realization of the importance of industrial safety with technological advancement in manufacturing.

Most of today’s advanced & computer-controlled industrial processes involve large amounts of energy and have the potential for devastating accidents. So a well-engineered & reliable industrial safety system is essential for protection against those accidents and loss of life.

The safety movement was initially started in 1912 with the first cooperative safety congress and the organization of the national safety council of the USA.

What is Industrial Safety?

As per Wikipedia :

“An industrial safety system is a countermeasure crucial in any hazardous plants such as oil and gas plants and nuclear plants. They are used to protect humans, industrial plants, and the environment in case of the process going beyond the allowed control margins.”

In simple words:

“The management of all operations and procedures in an industry in order to protect its employees and assets by minimizing hazards, risks, accidents, and near misses” called the Industrial Safety .”

Why industrial safety is necessary?

The thousand of industrial accidents every year caused the realization of the importance of industrial safety with technological advancement in manufacturing . The dangers of human life are increasing day by day.

In order to avoid accidents, employees must be aware of industrial safety principles & danger areas of that industry. The following are some reasons why Industrial safety is necessary:

- For the safety of people in their workplaces

- For protecting the environment against damage from industrial accidents

- For protecting businesses against serious losses from damage to plant and machinery

- For eliminating accidents causing work stoppage and production loss.

- For creating awareness of the good practices available for the delivery of effective safety instrumented systems

- For providing basic training in well-established techniques for engineering of safety systems

- For assisting engineers and technicians to support and participate in the safety systems activities at their work with good background knowledge of the subject

- For being aware of what can go wrong and how to avoid it.

Because of safety first rule, all industrial personals must be trained enough about safety aspects of man, machines, and material & other infrastructure facilities for avoiding minor or major accidents. Safety is the first requirement and every industrial employee must learn safety measures even before he starts working on a machine or equipment.

Objectives of Industrial Safety

A practical goal of industrial safety is to lighten the environmental impact on the manufacturing unit and each person and the role of the industrial safety professionals is to find leverage or opportunities for considerable improvement using practical effort. The objectives of industrial safety systems are as follows:

- Industrial safety is needed to check all the possible chances of accidents for preventing loss of life and permanent disability of any industrial employee, any damage to machine and material.

- It is needed to eliminate accidents causing work stoppage and production loss.

- It is needed to reduce workman’s compensation, insurance rate, and all the cost of accidents.

- It is needed to achieve better morale among industrial employees.

- It is needed to increase production means to a higher standard of living.

- It is needed to prevent accidents in the industry by reducing any hazards.

Planning of Industrial Safety

In industries, the no. of fire hazards, accidents, industrial disasters may be reduced through careful safety planning. All those unfortunate events can be avoided by effective planning for safety. Some important considerations for industrial safety are the following:

- Proper Plant Layout

- Proper Fire Prevention system

- Health & Hygiene

- Proper Safety Training

- Proper Alarms And warning systems

- Appropriate sensors and safety gears for employees

- Sufficient lighting in the work area as well as the pathways

- Cleanliness & dryness of shop floor

- Proper pressure gauges and other safety equipment

- Electrically insulation

- Proper signboards for safety instructions

COMMON SOURCES OF ACCIDENTS

Accidents take place unexpectedly causing injury & loss of men, machines, materials of that industry. Revolving, rotating, and moving parts of machines may be the sources of danger and require guarding for protection against accidents and Many such major sources are following.

- Low light machine operation areas.

- Revolving parts like pullies, flywheels, wheels, fans, gears, gear trains, gear wheels, etc.

- Intermittent feed mechanisms like tool feed of planer, table feed of a shaper, ram feed of power presses, and similar other applications.

- Revolving shafts, spindles, bars, mandrels, chucks, followers, and tools like drills, taps, reamers, milling cutters, and boring tools, etc.

- Rotating worms and spirals enclosed in casings, such as in conveyors and revolving cutting tools, like milling cutters, circular saw blade, saw band, circular shears, and grinding wheels, etc.

- Reciprocating tools and dies of power presses, spring hammer, drop hammers, and reciprocating presses, knives, and saw blade such bow saw, shearing and perforating machines and the cutting and trimming machine and power hacksaws, etc.

- Electrical wires, switches, motors & control panels.

- Oily & wet and dirty shop floor.

- Moving weights, such as in hydraulic accumulator or in slotting machines for counter-balance.

- Nips between racks and pinions of machine parts

- Nips between reciprocating parts and fixed components, such as between shaper table and the fixture mounted on it or a planer table and table reversing stops, etc.

- Nips between crank handle for machine controls and fixed parts.

- Projecting sharp edge or nips of belt and chain drives; via a belt, pulleys, chains sprockets, and belt fasteners, etc.

- Cutting edges of endless band cutting machines, woodworking, and log cutting metal find stone-cutting band saws, cloth-cutting band knives, etc.

- Pressure containers like pneumatic cylinders, boilers, etc.

Industrial Accidents and Their Types

There are various types of common accidents as follows:

Near Accident: Accidents with no damage or injury are called near-accidents.

Trivial: An accident with very little damage is called trivial.

Minor Accident: It is an accident with damage and injury more than trivial.

Serious Accident: An accident with heavy damage and a lot of injuries is called Serious Accidents.

Fatal: It is an accident with very heavy damage. There may be a loss of lives also.

3 Causes of Accidents

The accidents may take place due to the three following causes:

Human Causes

Mechanical causes, environmental causes.

Very common human causes for accidents are as follows:

- Operating or working at an unsafe speed.

- Working on unsafe or dangerous equipment or machinery.

- Operating machines without knowledge, without safety precautions, or without safety devices.

- Working for a long duration of work.

- Use of improper tools.

- Working with mental worries, ignorance, carelessness, nervousness, dreaming, etc.

Very common mechanical causes of accidents are as follows:

- Use of unguarded or improper guarded machines or equipment.

- The use of old, poorly maintained or unsafe equipment may result in accidents.

- Improper material handling system and improper plant layout.

- Not using safety devices such as helmets, goggles, gloves, masks, etc.

- Working at improper temperature and humidity causes fatigue to the workers for chances of accidents.

- he presence of dust fumes and smoke in the working area.

- Poor housekeeping, congestion, blocked exits, bad plant layout, etc.

- Inadequate illumination.

- Improper ventilation may also lead to industrial accidents.

- Lack of cleanliness.

Scope of Industrial Safety training for workers

Understanding of the importance of workplace safety instructions.

Workers, machine operators, and other employees should need to know & understand all the safety instructions. They should also understand how a work-related injury can affect their lives. Safety instructions boards must be placed in an appropriate location in order to everybody who enters the workplace can read it first.

Identifying Workplace Hazards

There are a lot of visible and hidden hazards that can cause accidents. So every worker or employee should need to have a concrete understanding of the types of hazards that exist in the workplace and how to recognize them. Key hazards include machinery; spares, vehicles; electrical hazards; noise, chemicals, stress, and ergonomic hazards, which can all be presented in a visible or hidden form.

Understand How to Reduce Risk

Every machine operator or worker must be trained to reduce accident risk. They should learn to connect hazards and hazard controls, like sensors, alarms, machine guards, and fire extinguishers. They should always use personal protective equipment like safety shoes, glasses, gloves, etc.

How to React in an Emergency

Even if all of the other hazards they may be exposed to are adequately controlled, workers may face emergencies at work right alongside their non-disabled coworkers. They need to know how to recognize an emergency and must be trained in emergency procedures.

Responsibilities at Work

Every employee and workers need to know that they are responsible for knowing and following all safety and health rules and safe work practices, reporting all injuries, using the safety gear that’s provided for them, and reporting any unsafe conditions that they see.

Reporting the Problems at Work

Once they know how to identify workplace hazards or other safety-related problems, employees must share that information with a responsible officer like a supervisor other individuals who are responsible for solving safety problems.

The safety and productivity of people, machines, and processes is a key element of any sustainable business. Industrial safety systems have been used for many years to perform safety functions in the manufacturing industries. In most situations, safety is best achieved by inherently safe process design, Protection layer systems such as sensors, alarms, and personal protection equipment.

These may be combined with protective systems to address any residual identified and counter risk. Protective systems can rely on different technologies such as chemical, mechanical, hydraulic, pneumatic, electrical, electronic, and programmable electronic.

Companies and the operators who manage their production facilities demand the highest level of safety. This high level of safety helps protect personnel, the environment, and assets while maintaining maximum uptime and minimal operational disruption.

Help Your Friends

This information found me when I needed it the most,thank you so much

Sir Very good and nice information Thanks .

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

This site uses Akismet to reduce spam. Learn how your comment data is processed .

- Preferences

Industrial Process Safety Lessons from major accidents and their application in traditional workplace safety and health - PowerPoint PPT Presentation

Industrial Process Safety Lessons from major accidents and their application in traditional workplace safety and health

Industrial process safety lessons from major accidents and their application in traditional workplace safety and health graham d. creedy, p. eng, fcic, feic – powerpoint ppt presentation.

- How I got into this

- The evolution of the philosophy of industrial safety and prevention of major accidents

- Some key insights and concepts

- How these apply to management of workplace safety in various sectors and at different levels of the organization

- 1984 Bhopal accident is wake-up call to chemical industry

- Industry responsibility to understand and control hazards and risks

- Responsible Care launched in Canada

- Principles, codes, commitment, tools, support, progress tracking, verification

- Major Industrial Accidents Council of Canada 1987-1999

- Process hazard

- A physical situation with potential to cause harm to people, property or the environment

- Risk (acute)

- probability x consequences of an undesired event occurring

- Good companies can be lulled into a false sense of security by their performance in personal safety and health

- They may not realise how vulnerable they are to a major accident until it happens

- Subsequent investigations typically show that there were multiple causes, and many of these were known long before the event

- People often assume systems work as intended, despite warning signs

- Examples of good performance are cited as representing the whole, while poor ones are overlooked or soon forgotten

- Analysis of failure modes and effects should include human and organizational aspects as well as equipment, physical and IT systems

- Process safety management

- Recognition of seriousness of consequences and mechanisms of causation lead to focus on the process rather than the individual worker

- Many of the key decisions influencing safety may be beyond the control of the worker or even the site they may be made by people at another site, country or organization

- Causes differ from those for personnel safety

- Need to look at the whole materials, equipment and systems and consider individuals and procedures as part of the system

- Management system approach for control

- Accountability

- Process Knowledge and Documentation

- Capital Project Review and Design Procedures

- Process Risk Management

- Management of Change

- Process and Equipment Integrity

- Human Factors

- Training and Performance

- Incident Investigation

- Company Standards, Codes and Regulations

- Audits and Corrective Actions

- Enhancement of Process Safety Knowledge

- What is the safety policy and culture (written, unwritten)?

- How are the following handled?

- Establishing what has to be done

- Benchmarking

- Communicating

- Assigning accountabilities

- Ensuring that it gets done

- Monitoring and corrective action

- Evidence (documentation) and audit process

- Resourcing not only for ideal but for anticipated conditions

- Balancing with other priorities

- How are exceptions handled?

- Dont know (and perhaps dont know that they dont know)

- Did know, but may have forgotten or could have gaps in application (and perhaps dont realize it)

- Excellent guidance exists but how is it being used?

- Can be applied to adoption of new ideas

- Categories differ by ability and more importantly, motivation

- Management commitment at all levels

- Status of process safety compared to other organizational objectives such as output, quality and cost

- Objectives must be supported by appropriate resources

- Be accessible for guidance, communicate and lead

- Change of process technology

- Change of facility

- Organizational changes

- Variance procedures

- Permanent changes

- Temporary changes

- Design to handle all anticipated conditions, not just ideal or typical ones

- Make sure what you get is what you designed (construction, installation)

- Test to make sure the design is indeed valid

- Make sure it stays that way

- Preventative maintenance

- Ongoing maintenance

- Be especially careful of automatic safeguards

- Consider operator as fallible human performing tasks in background

- Design for error tolerance, not just prevention

- Realization of significance of sociocultural factors in human thought processes and hence in behaviours

- People, and most organizations, dont intend to get hurt (have accidents)

- To understand why they do leads us eventually into understanding human behaviour, both at the individual and organizational level, and involves

- Physical interface

- Psychological interface

- Perception, decision-making, control actions

- Human thought processes

- Basis for reaching decisions

- Ideal versus actual behaviour

- Social psychology

- Relationships with others

- Organizational behaviour

- Instead of looking at the ways in which people can fail, look at how they function normally

- Skill-based

- Rapid responses to internal states with only occasional attention to external info to check that events are going according to plan

- Often starts out as rule-based

- Rules need not make sense they only need to work, and one has to know the conditions under which a particular rule applies

- Knowledge-based

- Used when no rules apply but some appropriate action must be found

- Slowest, but most flexible

- Immediately adverse effect

- Similar to unsafe act

- Effect may not be noticeable for some time, if at all

- Similar to resident pathogen. Unforeseen trigger conditions could activate the pathogens and defences could be undermined or unexpectedly outflanked

- Hazard of material known, but lack of awareness of potential system failure mode leads to defective procedure design through management decision

- Hazards known, but defences compromised by apparently benign change

- Latent error in procedure design creates vulnerability to likely execution error

- Hazard of material not obvious (despite history)

- Latent error allowed dust to accumulate, creating conditions for subsequent events

- Aerospace and nuclear show how significant human and organizational aspects can be even where the obvious signs of failure are technical in nature

- Finance shows

- Relevance of such factors without technical distractions

- How fast a system can deteriorate once controls are relaxed

- How wrong risk assessments can influence bad policy decisions

- The relevance of organizational factors has also been graphically and tragically revealed in the inquiry reports of recent UK transportation and offshore oil disasters.

- Prior to ..., senior managers in all the organizations propounded the pre-eminence of safety. They believed in the efficacy of the regulatory system, in the adequacy of their existing programs, and in their confidence of the skills and motivation of their staff.

- The inquiry reports reveal that their belief in safety was a mirage, their systems inadequate, and operator errors and violations commonplace.

- The inquiry reports stated that ultimate responsibility lay with complacent directors and managers who had failed to ensure that their good intentions were translated into a practical and monitored reality. Moreover, the weaknesses so starkly revealed were not matters of substantial concern to the regulatory authorities before the accidents.

- Organizational culture

- the way we do things around here when no-one is looking

- increasingly being recognized as one of the most important factors in major accidents

- perceived balance between output, cost and safety is heavily dependent on this culture, and influences whether personnel work in a certain way because they believe the company and their co-workers feel it is the right way to do things, or whether they are simply going through the motions.

- Demographic effects

- Experienced cohort leaving or left

- Skills transfer senior gt (middle) gt junior

- Replacements understand the way something is done, but not why it is done that way, the potential consequences of doing it differently and how to detect and recover from undesired actions

- We are starting to see lowered standards of design and supervision that fifteen years ago would have been unthinkable in the chemical industry (Challenger, 2004)

- What does an organizations investigation of its failures reveal about its

- Management system?

- Never realized problem could occur (benchmarking error)

- was it treated as a unique deficiency?

- was there a broader review of the benchmarking process to find if there are other areas where knowledge could be deficient?

- Thought situation would be acceptable but didnt realize full implications until it happened

- Does it appear to be acceptable now?

- Was review of policy and accountability limited or broad in scope?

- System design

- Even if everything had been done as intended, problem would still have occurred

- How comprehensive was analysis of system deficiencies and practicality of solutions?

- How effective is action plan and follow through?

- Was review of system design limited or broad in scope?

- System execution (management system error)

- Problem occurred because someone or something did not perform as intended

- Did analysis consider why execution not as intended?

- Was corrective action appropriate and balanced?

- Was review of system execution limited or broad in scope?

- Finding out who youre dealing with

- Where is the organization on the curve? (generally, and re the specific issue or problem)

- Where are the people youre dealing with on the curve? (generally, and re the issue or problem)

- Finding out what to do

- Benchmark dont try to reinvent the wheel unless youre sure there isnt one already (or youve time and its fun to do so)

- Find out what others are doing about it

- Read the instructions

- Identify/define the issue

- If its likely to be regulated, check with government agencies, trade associations, web, internet

- If not regulated but likely good industry practice, check suppliers, other users of same material or item, other users of similar items, other industry contacts but test the info!!! (cross-check, ask if it makes sense)

- Check standard reference works, (Lees, CCPS, etc)

- Try to think of all situations that are likely to occur (process, eqpt, people)

- KISS, keep it user-friendly, show basis for decisions if practical to do so

- Follow up afterwards to see how its working

PowerShow.com is a leading presentation sharing website. It has millions of presentations already uploaded and available with 1,000s more being uploaded by its users every day. Whatever your area of interest, here you’ll be able to find and view presentations you’ll love and possibly download. And, best of all, it is completely free and easy to use.

You might even have a presentation you’d like to share with others. If so, just upload it to PowerShow.com. We’ll convert it to an HTML5 slideshow that includes all the media types you’ve already added: audio, video, music, pictures, animations and transition effects. Then you can share it with your target audience as well as PowerShow.com’s millions of monthly visitors. And, again, it’s all free.

About the Developers

PowerShow.com is brought to you by CrystalGraphics , the award-winning developer and market-leading publisher of rich-media enhancement products for presentations. Our product offerings include millions of PowerPoint templates, diagrams, animated 3D characters and more.

Home Collections Education Safety

Safety Presentation Templates

Our safety powerpoint templates and google slides themes cover a wide range of topics, helping you create professional and engaging presentations that will help you communicate your safety message effectively. it includes slides on fire safety, workplace safety, hazard prevention, etc. download your free safety templates.

We're here to help you!

What are safety presentation templates.

Safety presentation templates are designed with eye-catching safety themes, backdrops, designs, and icons. Through appealing pictures and designs, these templates may explain the value of Safety, the guidelines for Safety, and the advantages of staying safe.

Where can we use these Safety Presentation Slides?

You can use these safety Presentation Slides at schools, colleges, public places, parks, Montessori schools, companies, and private sectors to share the importance of Safety through attractive visual cues and themes.

How can I make Safety Slides in a presentation?

For typical PowerPoint users, creating a presentation template is easy. However, you should use pre-made safety PowerPoint templates if you are a beginner and must create a presentation quickly.

Who can use Safety Templates?

The Safety template can be used by everyone who cares for people's Safety. Also, traffic police, teachers, parents, public persons, and students can use these templates to share vital safety rules while crossing the road, driving, walking, playing, injuries, accidents, unexpected natural disasters, and so much more.

Where can I find free Presentation Templates?

There is a ton of free Presentation templates available online. The challenge is finding the ideal templates for your needs. The templates' quality and layout design might not satisfy your purpose. Therefore, always seek out a dependable PowerPoint provider, such as Slide Egg.

- My presentations

Auth with social network:

Download presentation

We think you have liked this presentation. If you wish to download it, please recommend it to your friends in any social system. Share buttons are a little bit lower. Thank you!

Presentation is loading. Please wait.

UNIT IV - INDUSTRIAL SAFETY

Published by Justina Strickland Modified over 8 years ago

Similar presentations

Presentation on theme: "UNIT IV - INDUSTRIAL SAFETY"— Presentation transcript:

SESSION 8 TITLE 4 – HEALTH PROTECTION, MEDICAL CARE,WELFARE AND SOCIAL SECURITY PROTECTION.

Industrial Skills Personal Safety & Accident Prevention.

Undersecretariat for Social Welfare Department of Occupational Health and Safety The Automotive Industry Workers’ Compensation Claims and Official Mexican.

Revised: 11/08/2010 Environmental Health & Safety (EH&S) Management David L. Patterson Director, Environmental Health & Safety Cal Poly Pomona Web:

Managing Safety and Health, Overview Ron Hopkins, CFPS, CFEI TRACE Fire Protection and Safety Consultants. Ltd. Richmond, Kentucky.

Accident Prevention Programs What Will We Talk About? What is an accident? What is an accident prevention program? Basic elements of a program Where.

Accident Investigations

Why do accidents happen? Accidents happen for one or both of the following Unsafe acts & Unsafe conditions.

ACCIDENT IN WORKPLACE Department of Public Health Faculty of Medicine, UNPAD.

University of Minnesota Duluth Job Hazard Analysis Assessing Risk & Eliminating Hazards Prepared by: Mahjoub Labyad Environmental Health and Safety Office.

General Definitions NEBOSH Certificate definitions of commonly used words or phrases. John Johnston, AIIRSM Just a collection of a few words and phrases.

Safe Working Procedure – First Aid Learning Objectives: By the end of this program participants will be able to demonstrate their understanding of the.

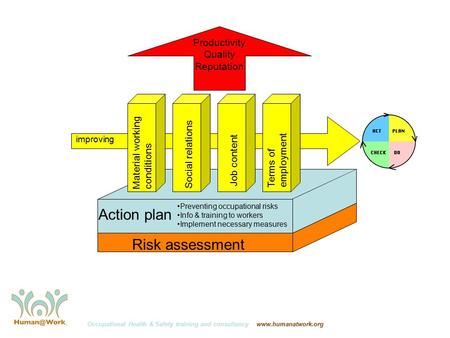

Job content Social relations Material working conditions Terms of employment Risk assessment Action plan Productivity Quality Reputation improving Occupational.

Hazard Identification and Control Courtesy of the Public Education and Conferences Section Oregon Occupational Safety and Health Division (OR-OSHA)

DIVISION OF YOUTH CORRECTIONS ESTABLISHING A SAFETY CULTURE.

Accident Prevention.

OSHA Long Term Care Worker Protection Train the Trainer Program Part 1: Introduction.

PHILOSOPHY OF ACCIDENT PREVENTION

Software Dependability CIS 376 Bruce R. Maxim UM-Dearborn.

International Health and Safety at Work

About project

© 2024 SlidePlayer.com Inc. All rights reserved.

- Customer Favourites

Industrial Safety Engineering

Powerpoint Templates

Icon Bundle

Kpi Dashboard

Professional

Business Plans

Swot Analysis

Gantt Chart

Business Proposal

Marketing Plan

Project Management

Business Case

Business Model

Cyber Security

Business PPT

Digital Marketing

Digital Transformation

Human Resources

Product Management

Artificial Intelligence

Company Profile

Acknowledgement PPT

PPT Presentation

Reports Brochures

One Page Pitch

Interview PPT

All Categories

- You're currently reading page 1

Stages // require(['jquery'], function ($) { $(document).ready(function () { //removes paginator if items are less than selected items per page var paginator = $("#limiter :selected").text(); var itemsPerPage = parseInt(paginator); var itemsCount = $(".products.list.items.product-items.sli_container").children().length; if (itemsCount ? ’Stages’ here means the number of divisions or graphic elements in the slide. For example, if you want a 4 piece puzzle slide, you can search for the word ‘puzzles’ and then select 4 ‘Stages’ here. We have categorized all our content according to the number of ‘Stages’ to make it easier for you to refine the results.

Category // require(['jquery'], function ($) { $(document).ready(function () { //removes paginator if items are less than selected items per page var paginator = $("#limiter :selected").text(); var itemsperpage = parseint(paginator); var itemscount = $(".products.list.items.product-items.sli_container").children().length; if (itemscount.

- Block Chain (2)

- Business Plan Word (17)

- Business Plans (4)

- Business Slides (3466)

- Circular (140)

- Cluster (10)

IMAGES

VIDEO

COMMENTS

This PPT presentation can be accessed with Google Slides and is available in both standard screen and widescreen aspect ratios. It is also a useful set to elucidate topics like Industrial Safety Management PPT. This well structured design can be downloaded in different formats like PDF, JPG, and PNG.

Atlantic Training specializes in online training concentrating on workplace safety, HR compliance and soft skills. This training powerpoint was created by Outreach Resources Workgroup (OTIEC). Objectives of the presentation are listed at the beginning slide, along with the definition of industrial hygiene and the four common types of health ...

Template 1- Focus on Employee Safety to Avoid Critical Incident. This PPT Template is a torchbearer for the activities that an organization can implement to employ the best employee safety practices in the construction business. It highlights the agenda for a safety program, major issues, goals, impact of safety training, and performance sheet.

Download Templates Of Welder Wearing Shield And Gloves At Work For Health Safety. 5. Encourage stretch breaks and regular meetings. Allow your employees to take stretch breaks because even a five-minute break can release muscle tension, loosen joints, and reduce the potential repetitive motion injuries.

Industrial Safety Market size was valued at $3.2 billion in 2020 and it is estimated to grow at a CAGR of 8.56% during the period 2021-2026. | PowerPoint PPT presentation | free to download. Industrial Safety Market Forecast 2021 - 2026 - Industrial Safety Market size was valued at $3.2 billion in 2020 and it is estimated to grow at a CAGR of 8 ...

Here are 24 safety moment ideas to improve general safety and inspire detailed presentations about the hazards in their work environments. Universal safety moment topics 1. Situational awareness. ... In industrial settings, safety moments can set the tone for the day. Whether you're reviewing a common topic or describing a new risk, an ...

industrial safety PPT Templates Download over 6,300+ complete free templates in high resolution. Ready-Made Slide Variety of templates for each industries.

Introduction to industrial-safety.ppt - Free download as Powerpoint Presentation (.ppt), PDF File (.pdf), Text File (.txt) or view presentation slides online. Scribd is the world's largest social reading and publishing site.

Industrial Safety presentation templates and google slides. SlideGeeks added 287 new products (e.g. Completely Researched Decks, Documents, Slide Bundles, etc), which included 2583 slides in total in the past 24 hours. 16 hours ago

The safety movement was initially started in 1912 with the first cooperative safety congress and the organization of the national safety council of the USA. What is Industrial Safety? As per Wikipedia: "An industrial safety system is a countermeasure crucial in any hazardous plants such as oil and gas plants and nuclear plants. They are used ...

The template comes in two color themes. You can choose from a color palette of cool blues, or you can go for some brighter and warmer tones. Both are eye-catching enough to capture the attention of your audience in an instant. Amazing compatibility. Be it Microsoft PowerPoint, Apple Keynote or Google Slides; this template works like a charm for ...

This is a completely adaptable PowerPoint template design that can be used to interpret topics like Industrial Relations Icon, Workplace Environment.So download instantly and tailor it with your information. Slide 1 of 10. Real Time Location System RTLS For Industrial Workplace Safety Enabling Smart Production DT SS.

Industrial Process Safety Lessons from major accidents and their application in traditional workplace safety and health Graham D. Creedy, P. Eng, FCIC, FEIC - A free PowerPoint PPT presentation (displayed as an HTML5 slide show) on PowerShow.com - id: 3b1d1b-NzFhM

Our safety PowerPoint templates and Google Slides themes cover a wide range of topics, helping you create professional and engaging presentations that will help you communicate your safety message effectively. It includes slides on fire safety, workplace safety, hazard prevention, etc. Download your free safety templates!

1 UNIT IV - INDUSTRIAL SAFETY. 2 INDUSTRIAL SAFETY DEFINITION: "Measures or techniques implemented to reduce the risk of injury, loss and danger to persons, property or the environment, in any facility or place involving the manufacturing, producing and processing of goods or merchandise.". 3 SIGNIFICANCE Safety is a value not a cost.

10. See our reviews. 4.5/5.0 - 2395 ratings Verified by LiveChat Mar. 2024 EXCELLENT SERVICE. Industrial Safety Engineering found in: Workplace Safety To Prevent Industrial Hazards Powerpoint Presentation Slides, Engineering Firm Safety Standard Operating Procedure, Real Time Location System RTLS For Industrial Workplace..